¶ Integrated Solution of Calibration

¶ Background

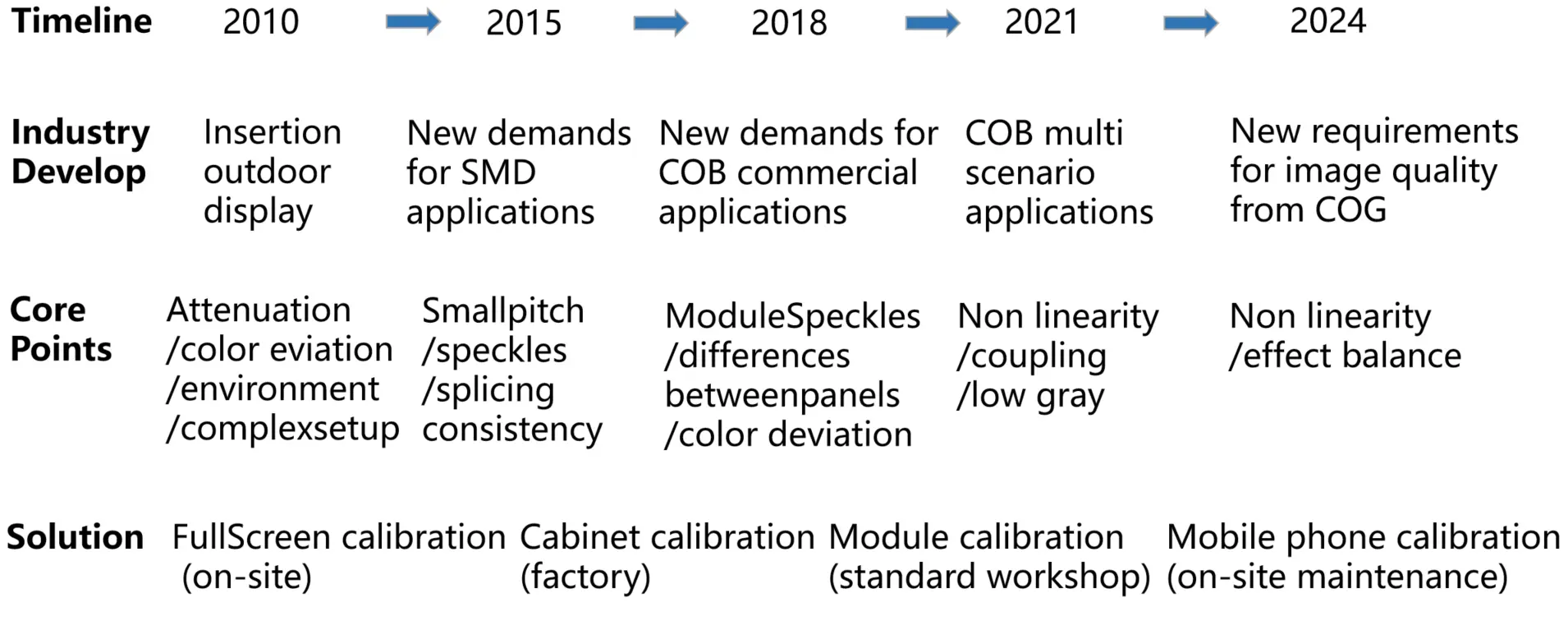

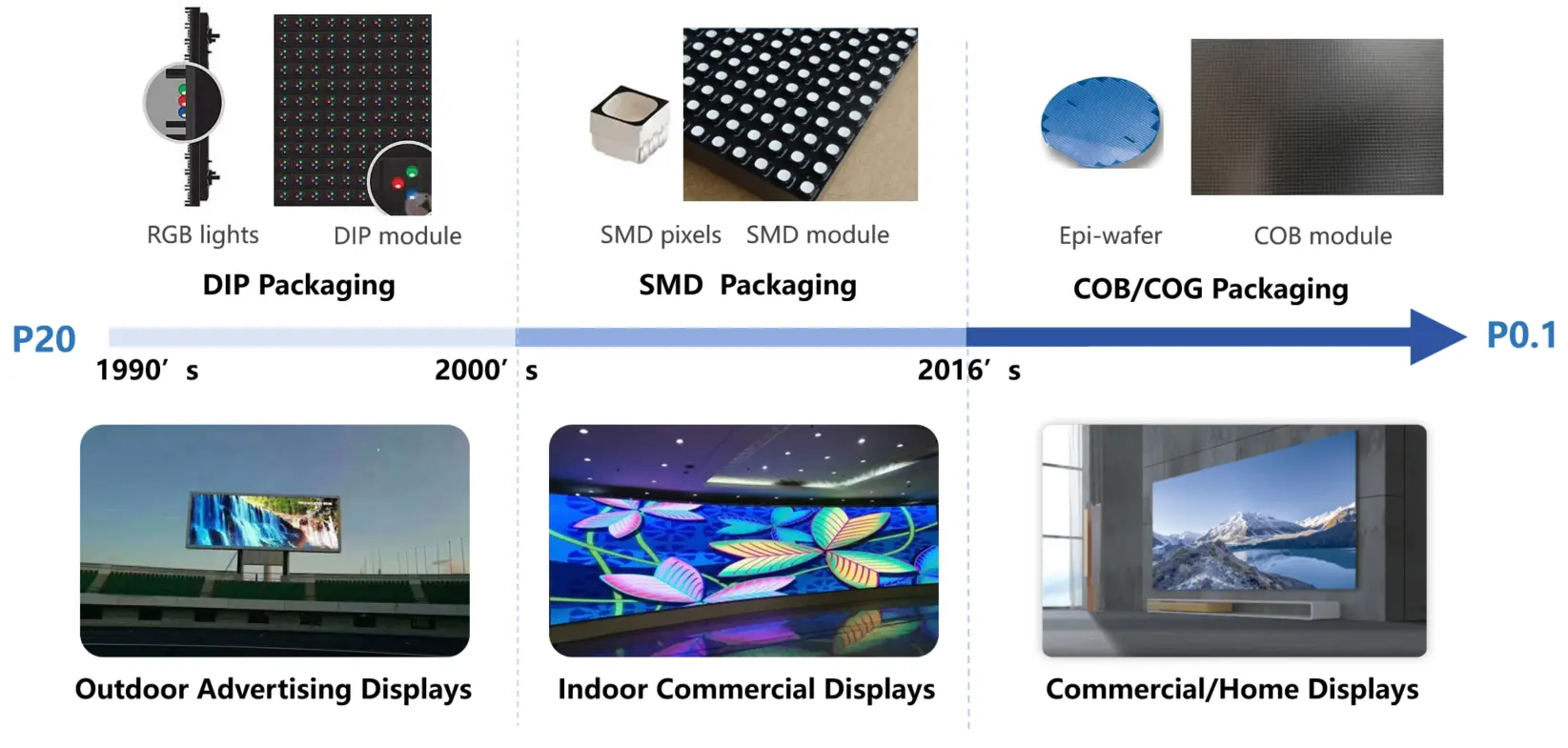

¶ Evolution of the Industry

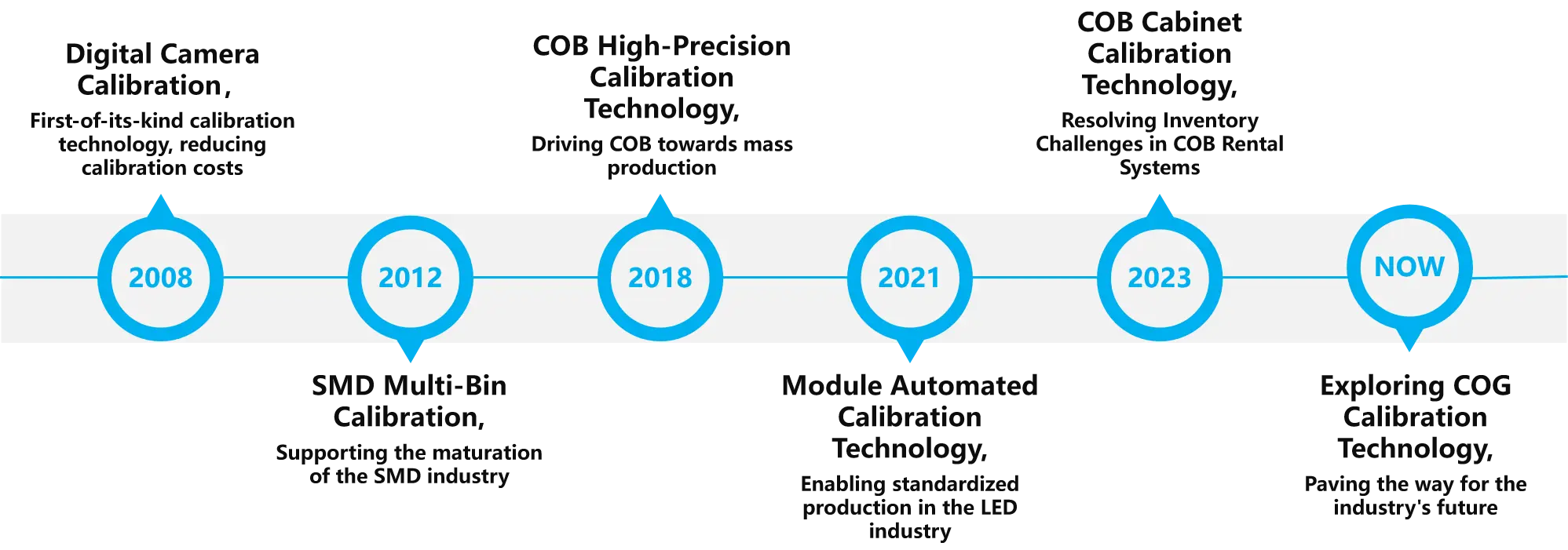

As the LED display industry continues to diversify and differentiate, the segmentation of market sectors has become increasingly defined. NovaStar has deeply analyzed the core challenges at each stage of industry development and has strategically developed a calibration technology system tailored to current demands.

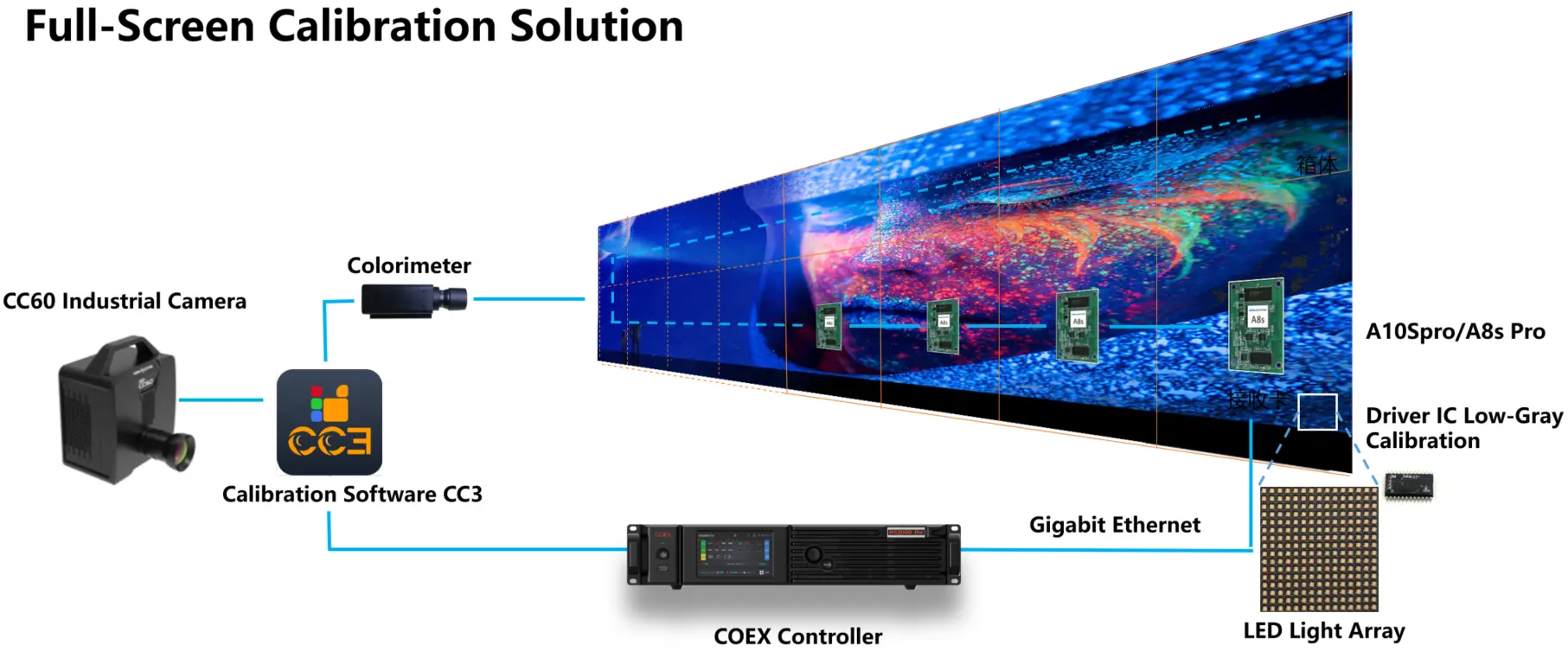

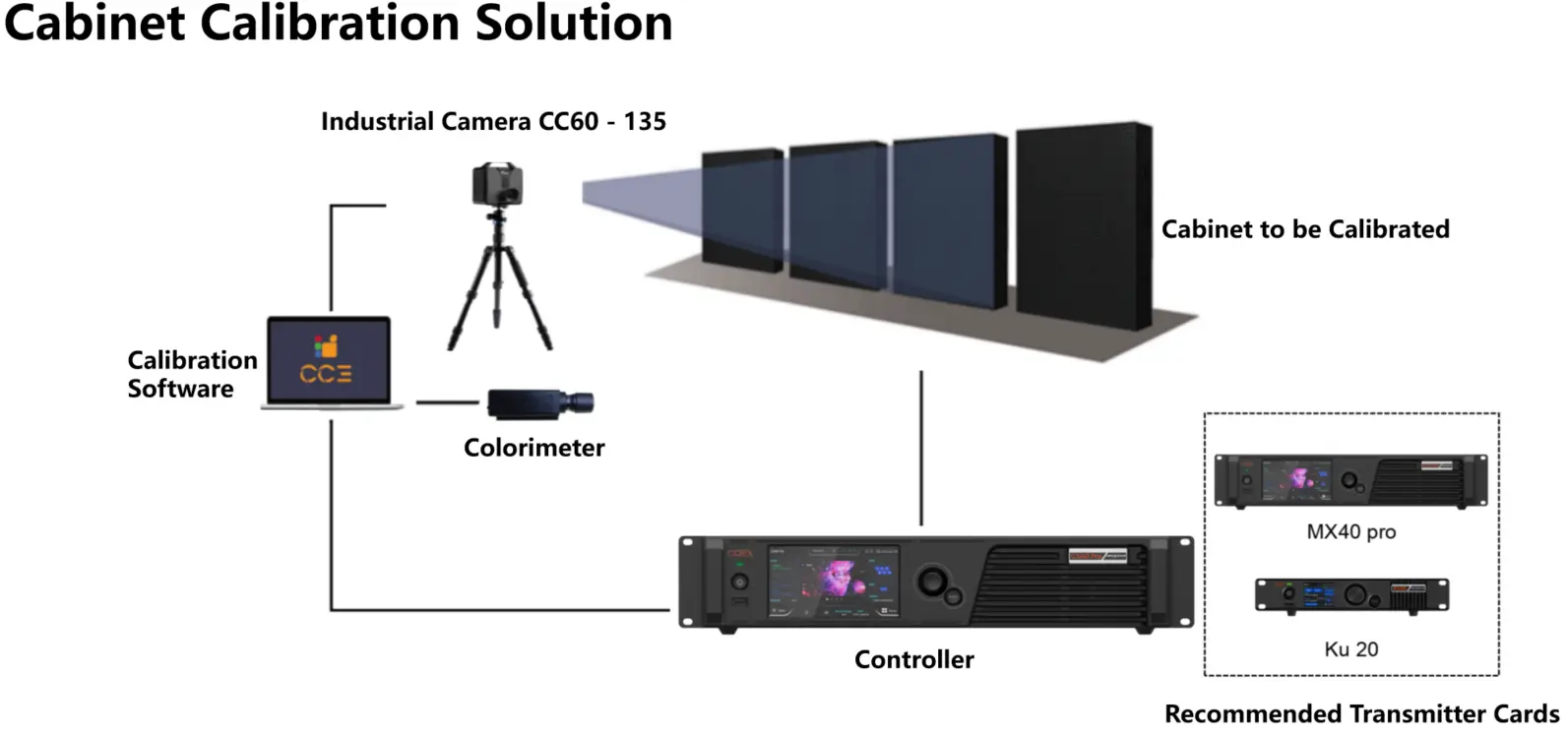

To address diverse application scenarios, including fixed installations, rental events, mass production in factories, and on-site installation debugging, NovaStar has innovatively introduced a full link of calibration solutions. These include full-screen calibration, cabinet calibration, automated production-line calibration, and smart phone calibration. By ensuring technical adaptability, NovaTech precisely meets the specialized needs of each market segment.

¶ Evolution of NovaStar Calibration Technology

¶ NovaStar Calibration Product Matrix

|

Type |

Solution |

Software |

Camera |

Controller |

Receiving Card |

| Cabinet Calibration | Chrome Calibration | CC3 |

Canon Cameras (70D/80D/90D/7D/R7/5D/50D/650D/450D/60D/6D/7D Mark II) |

KU20 /MX40 Pro |

A10s Pro |

| High Precision Calibration | Industrial Camera(CC60) | ||||

| Full Grayscale Calibration | |||||

| Low Grayscale Calibration | |||||

| Full Screen Calibration | Chrome Calibration |

CC3

|

Canon Cameras (70D/80D/90D/7D/R7/5D/50D/650D/450D/60D/6D/7D Mark II) |

COEX Controllers | |

|

High Precision Calibration |

Industrial Cameras(C3200/CC60) | ||||

|

Full Grayscale Calibration |

|||||

| Low Grayscale Calibration |

¶ Application Scenarios & Technical Solutions

¶ Full Screen Calibration

Challenge 1: The relaxation of COB mass-production tolerances introduces module-to-module variations and grayscale nonlinearity, making the displays unsuitable for fixed installation requirements.

Solutions:

- Image Booster Engine, resolving color deviation/mura defects

- High-precision camera capture, matching human visual response

- Stepwise grayscale calibration + driver IC tuning

Challenge 2:COG (Chip-on-Glass) packaging exhibits significant non-linearities across grayscale/color levels and noticeable inter-module variations, urgently requiring solutions for:

Solution: The integration of four core technologies comprehensively addresses industry challenges in COG packaging:

- COG Demura Technology resolves display uniformity issues

- Gamma/Color Temperature Correction Algorithm optimizes grayscale nonlinearity

- IRC Compensation Algorithm eliminates resistance-induced non-uniformity

- Thermal Compensation Technology mitigates thermal non-uniformity

¶ Cabinet Calibration

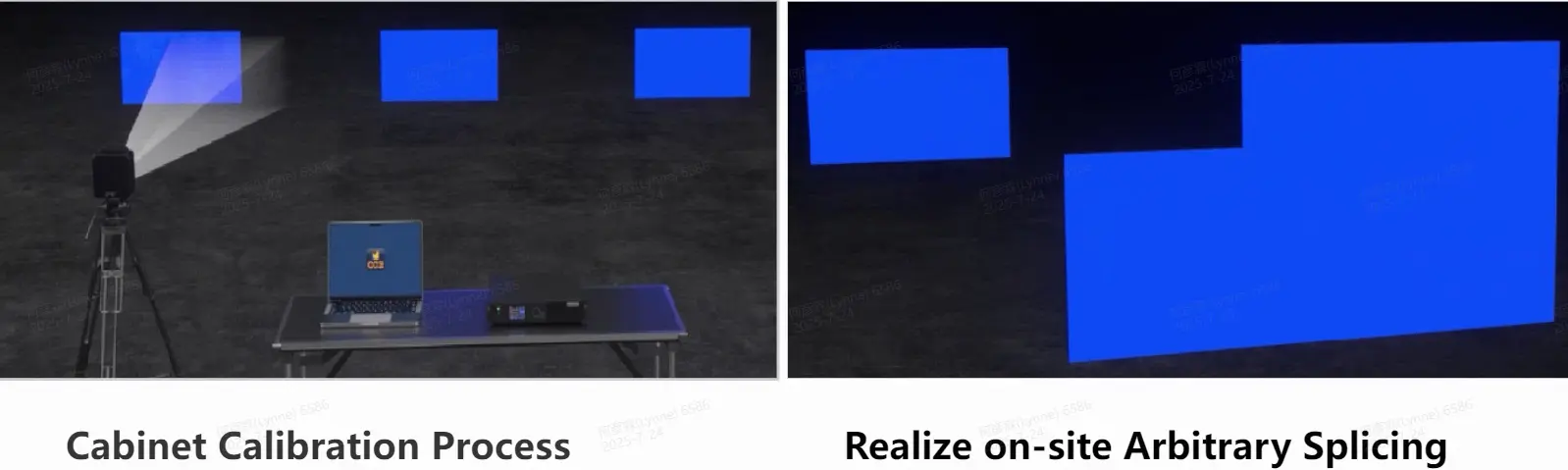

Challenge 1: To accommodate flexible factory inventory and on-site modular assembly requirements, achieving seamless arbitrary splicing of pre-calibrated cabinets is essential.

Solution:

- CC60 Sample Cabinet Calibration & Measurement

- Optimization For Curving Issue

- Single Cabinet Calibration in Batch

Result:

- Enables calibration with one optical path, one operator, one camera

- Improved efficiency: 3 minutes per cabinet calibration

- Reduces labor/resources input

- Ensures stable batch pre-production inventory

- Achieves on-site arbitrary splicing and flexible data management

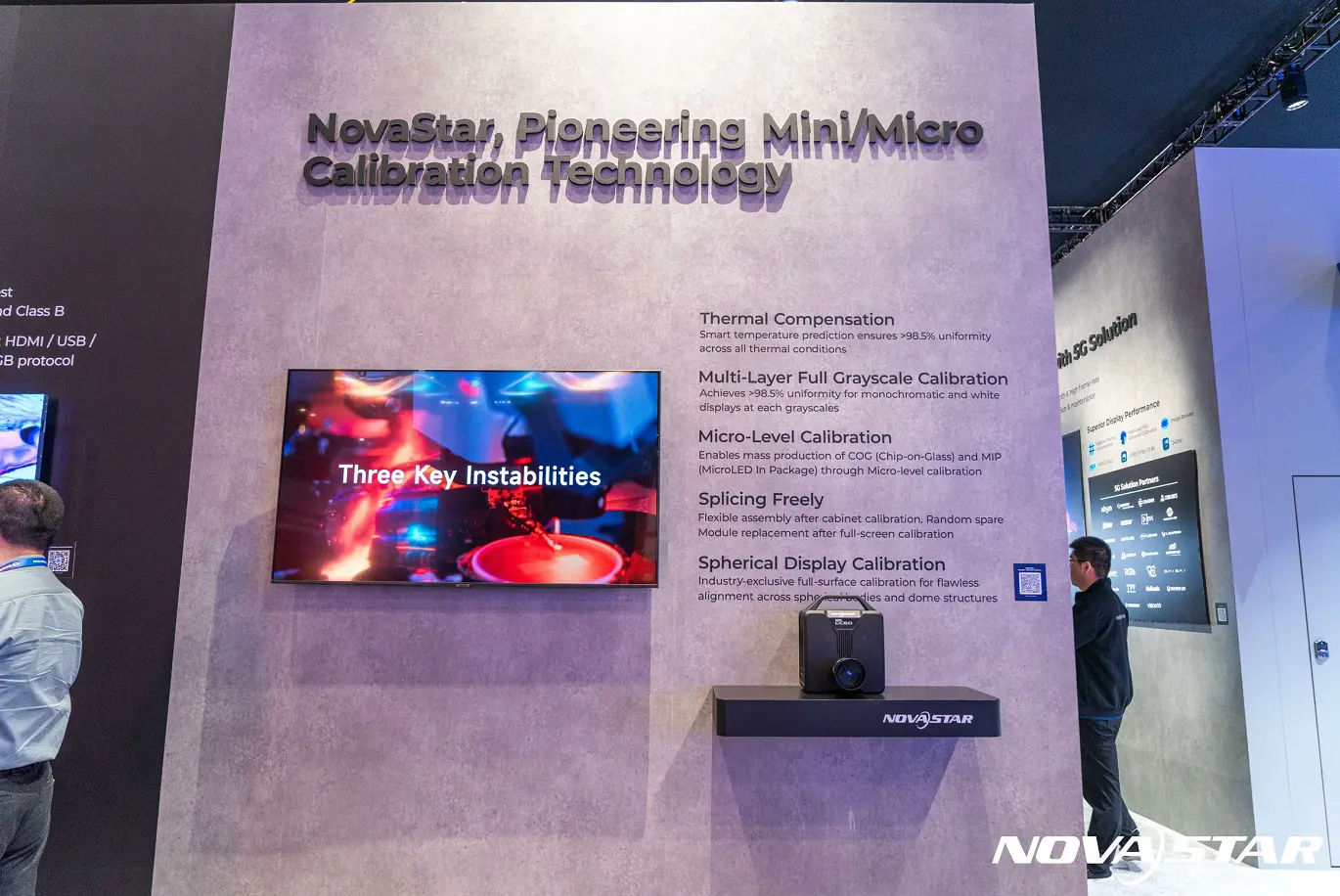

¶ Industry Leadership in Calibration Technology

¶ The Leading Calibration Technology

The uniform and refined image quality of MLED displays is the most immediate visual experience for audiences. This fundamentally relies on the underlying support of calibration technology, which represents the core focus of NovaStar's in-depth research in this field.

An ideal MLED display should be as uniform and smooth as silk, as pure and flawless as a blank sheet of paper. However, the LED industry currently faces its most prominent pain point: a lack of uniformity. Tracing back to the root cause, the issue stems from three major instability constraints.

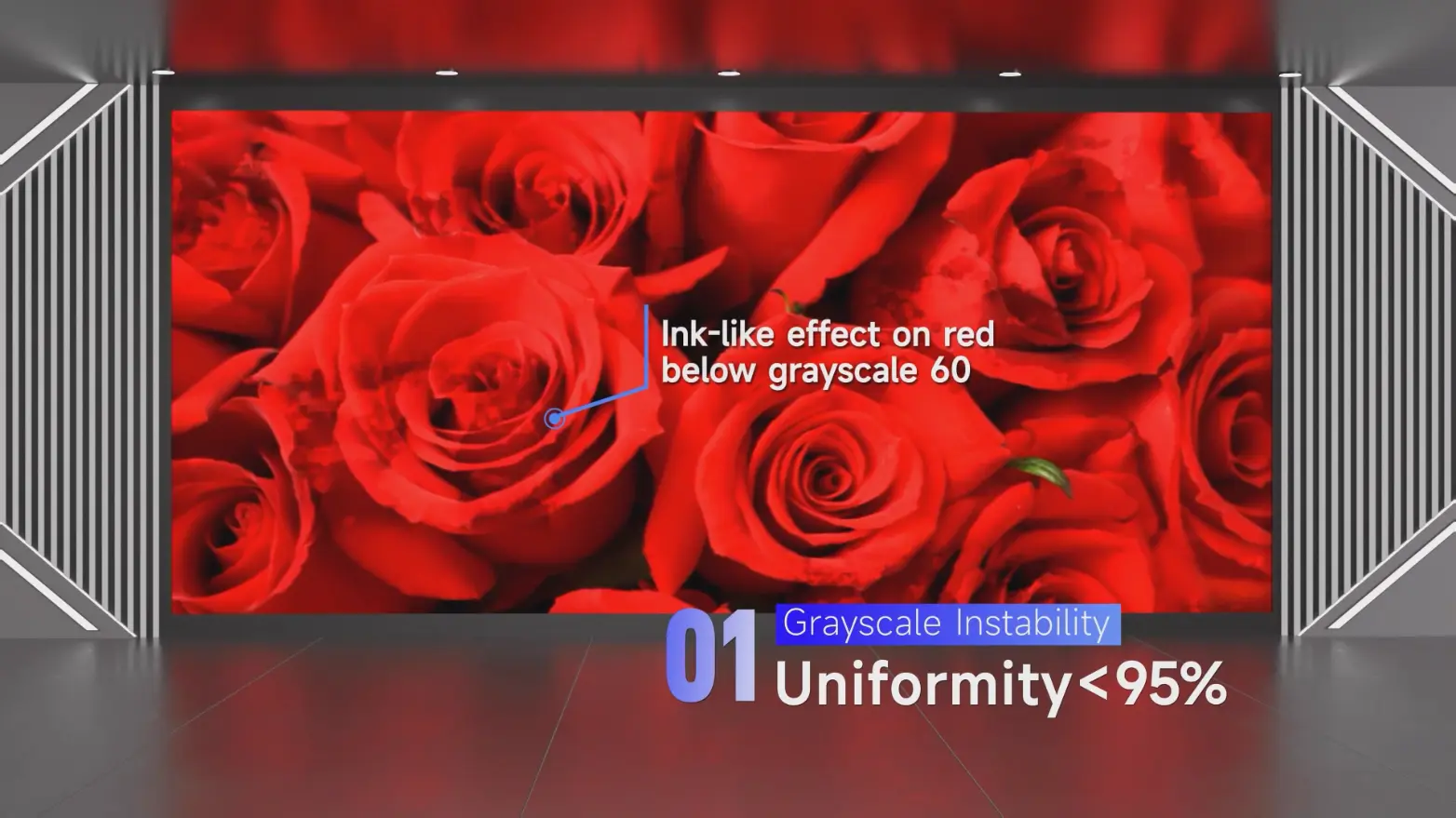

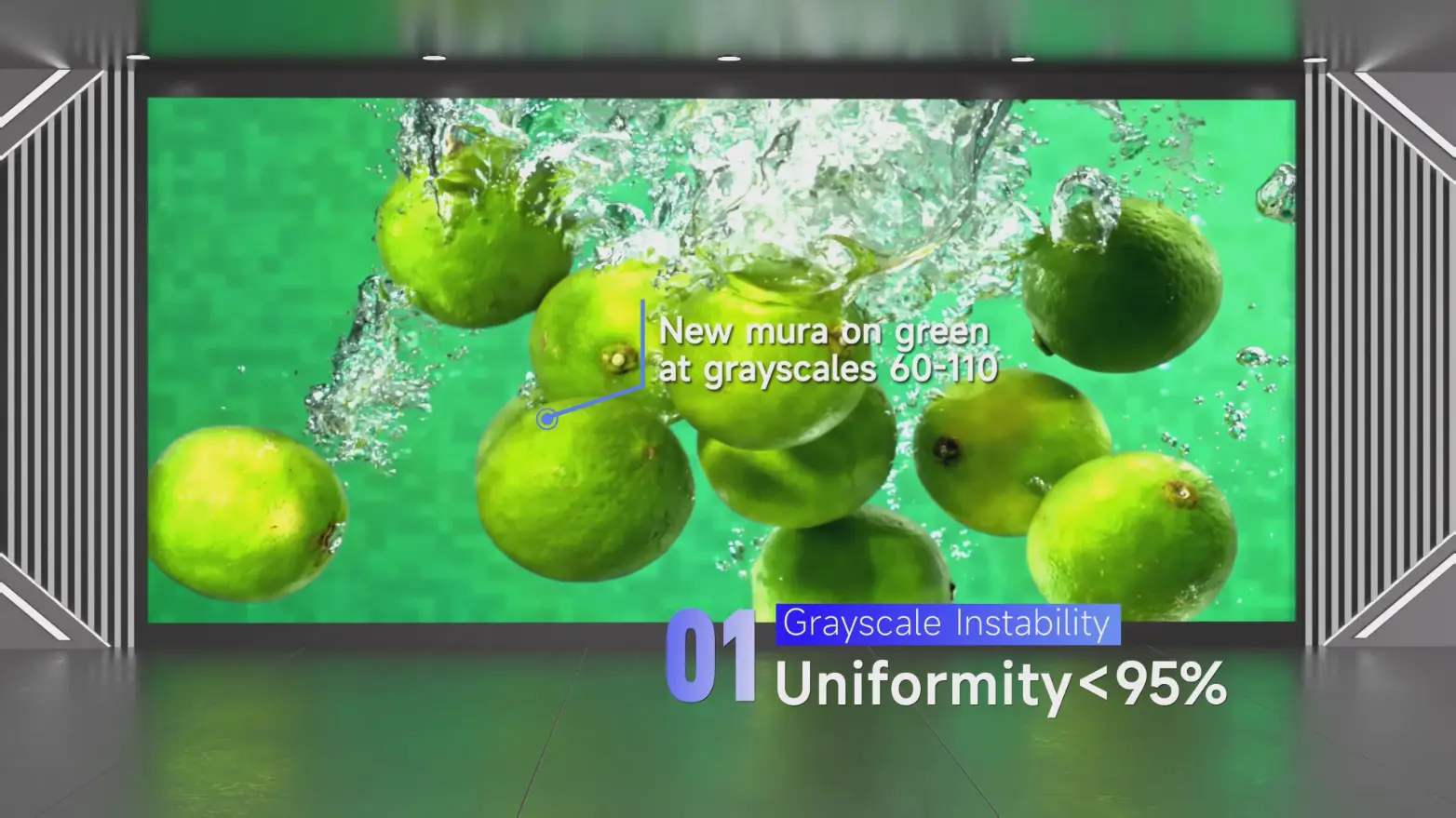

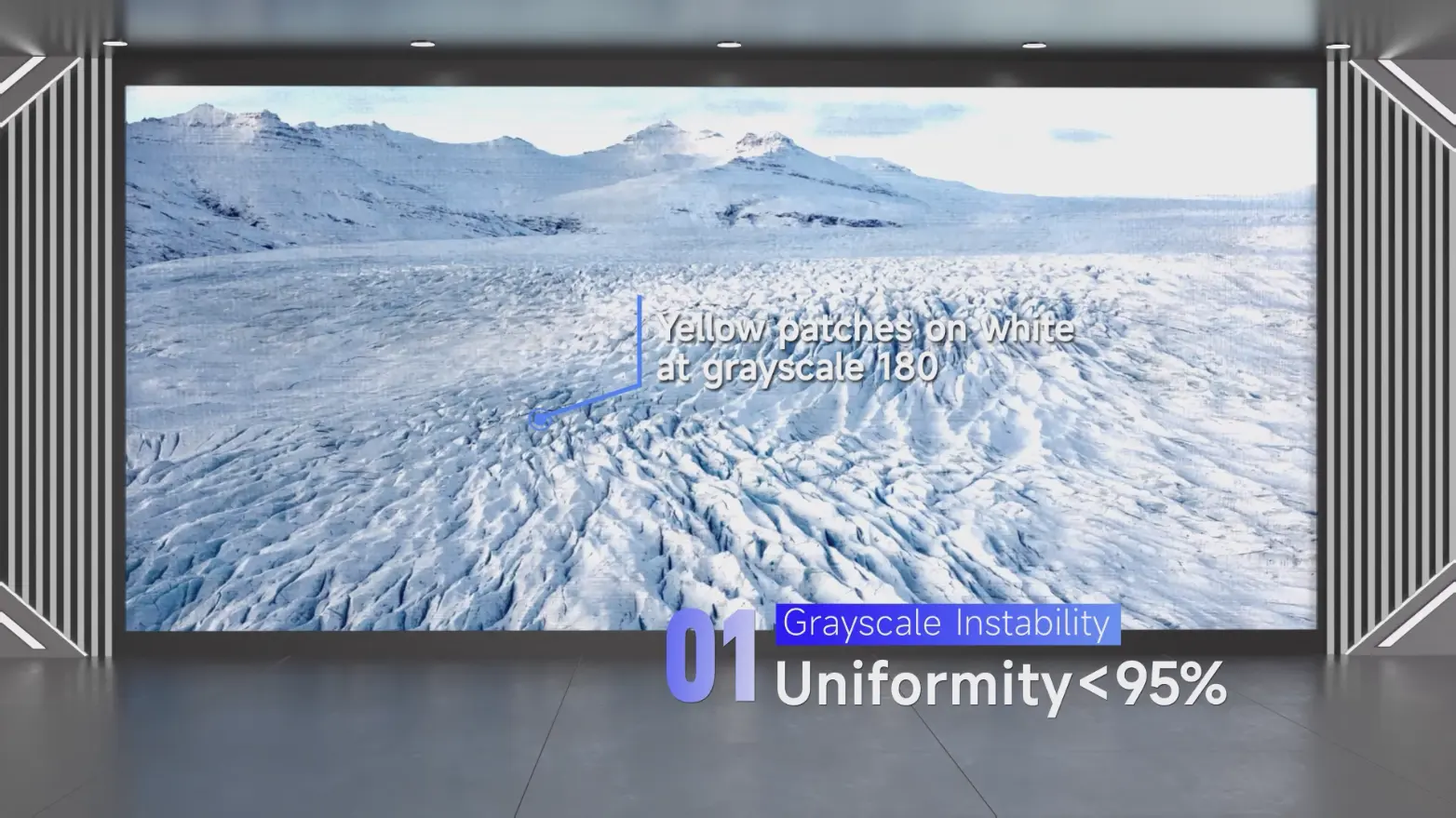

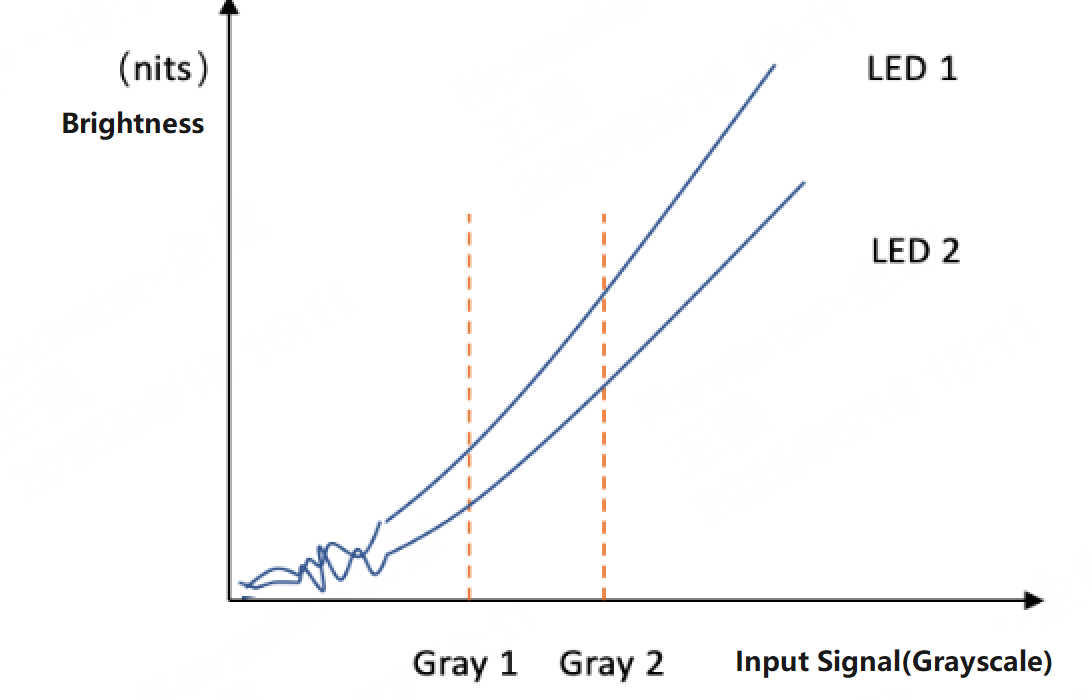

Issue 1: Grayscale Instability

MLED screens exhibit less than 95% uniformity across grayscale levels, with distinct artifacts manifesting differently in various grayscale ranges:

In low grayscale (≤60), "Red ink wash" effect is observed

In intermediate grayscale operation (60-110 range), MLED displays develop distinct green-dominant Mura patterns

At elevated grayscale levels (≥180 grayscale), MLED displays exhibit yellow-coupled discoloration in white fields.

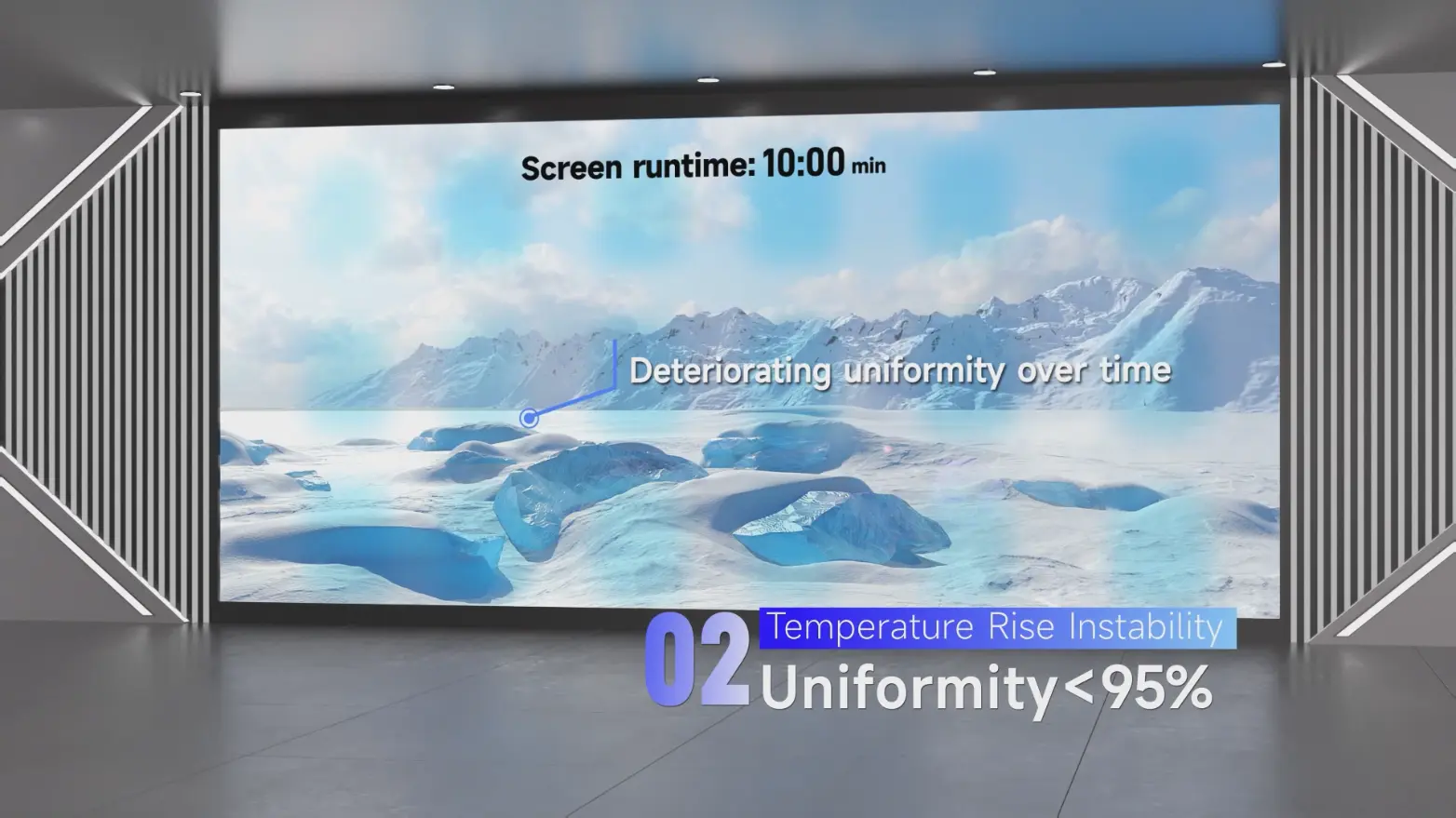

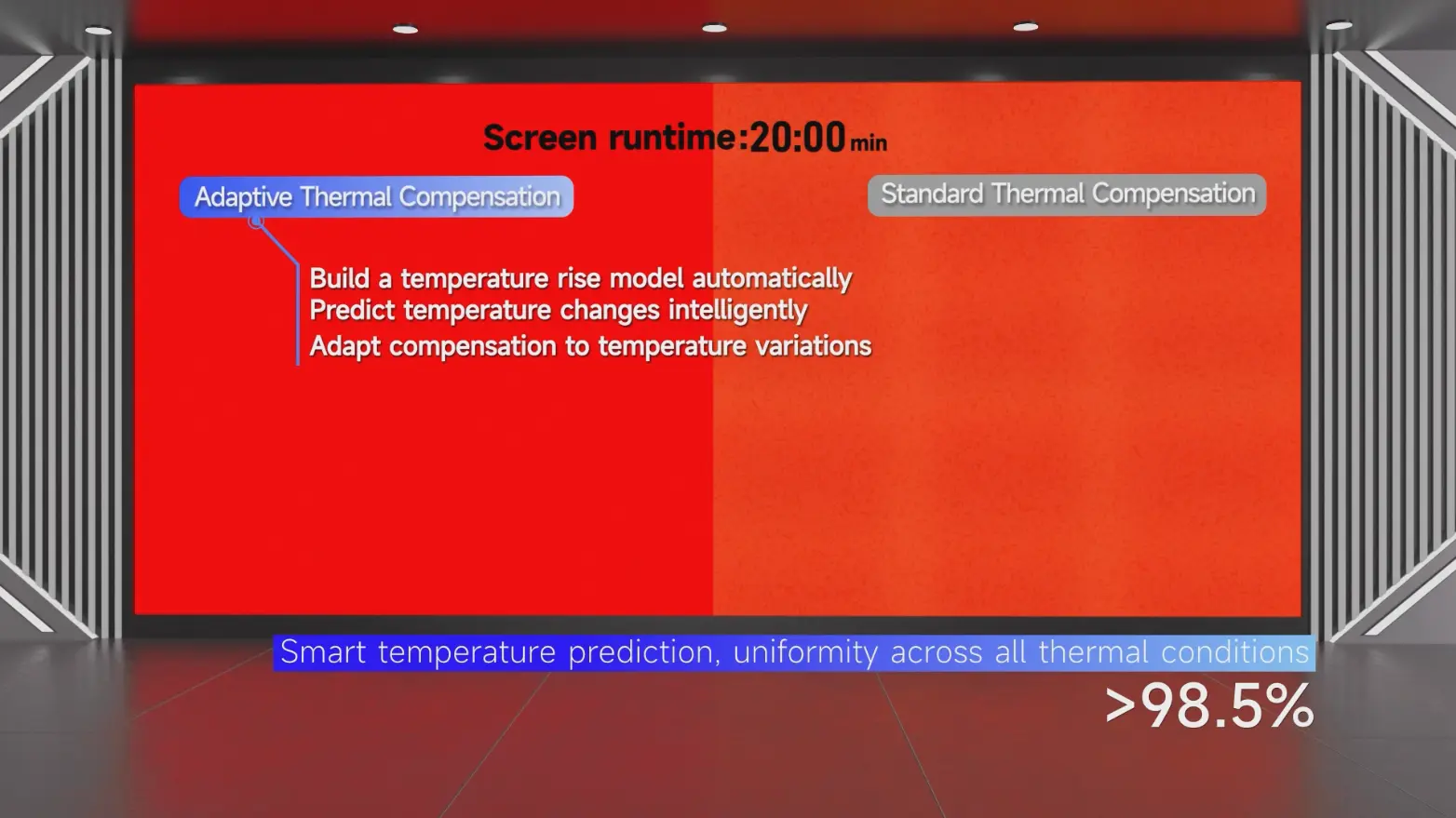

Issue 2: Temperature-Triggered Instability

MLED screens exhibit <95% uniformity across operating temperatures, with progressive uniformity degradation during extended operation. (Please refer to the thermal distribution diagram after 10 minutes of operation.)

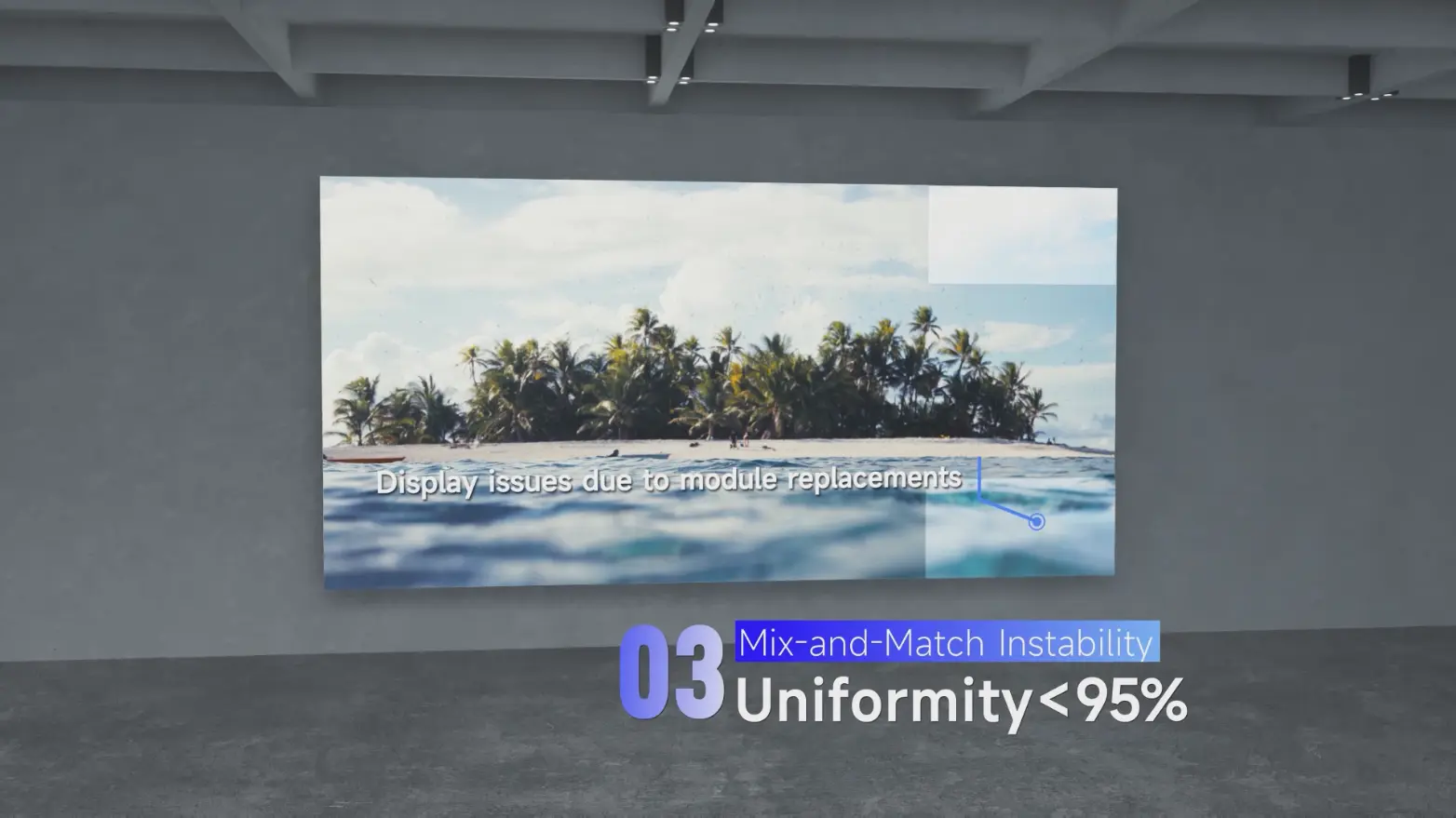

Issue 3: Compatibility Instability

During installation or maintenance, failure to properly and timely adjust LED dot coefficients results in on-site uniformity below 95%. This issue becomes particularly pronounced during long-term LED screen operation and module replacement.

NovaStar Calibration Solution

NovaStar's CC3 Calibration Solution delivers enhanced stability for Mini/Micro LED display performance. Our multi-method approach ensures:

- Grayscale stability

- Thermal consistency

- Component compatibility

Achieving >98.5% overall uniformity - making MLED displays as pristine as blank paper.

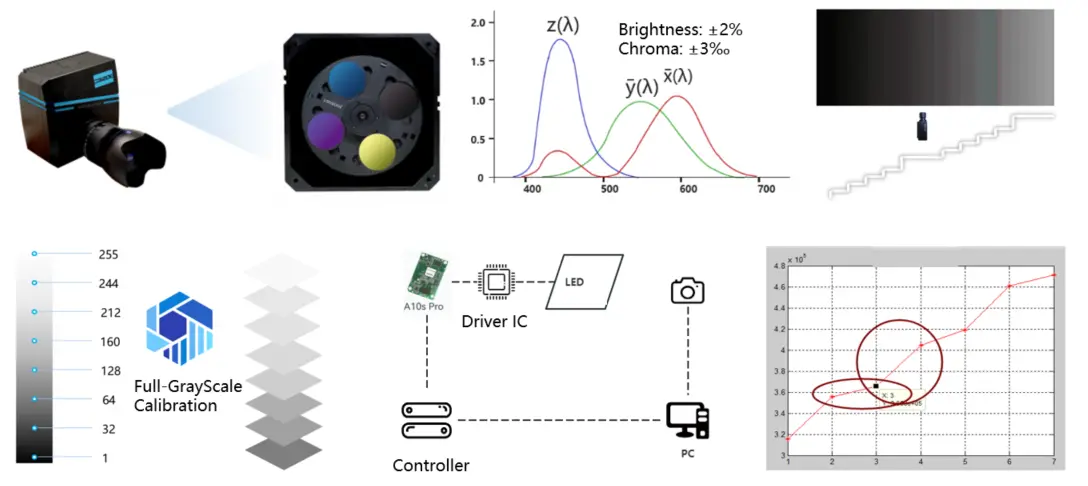

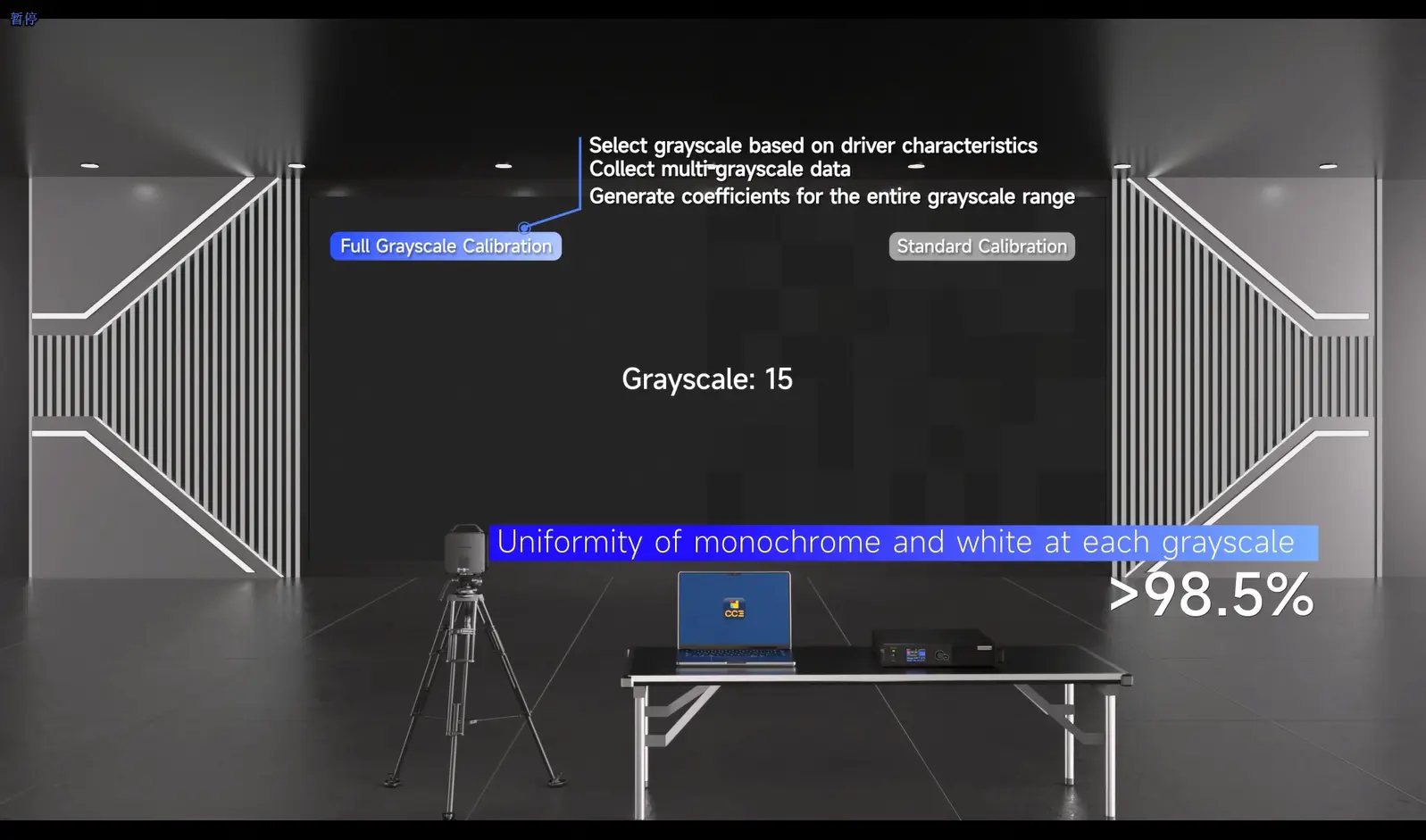

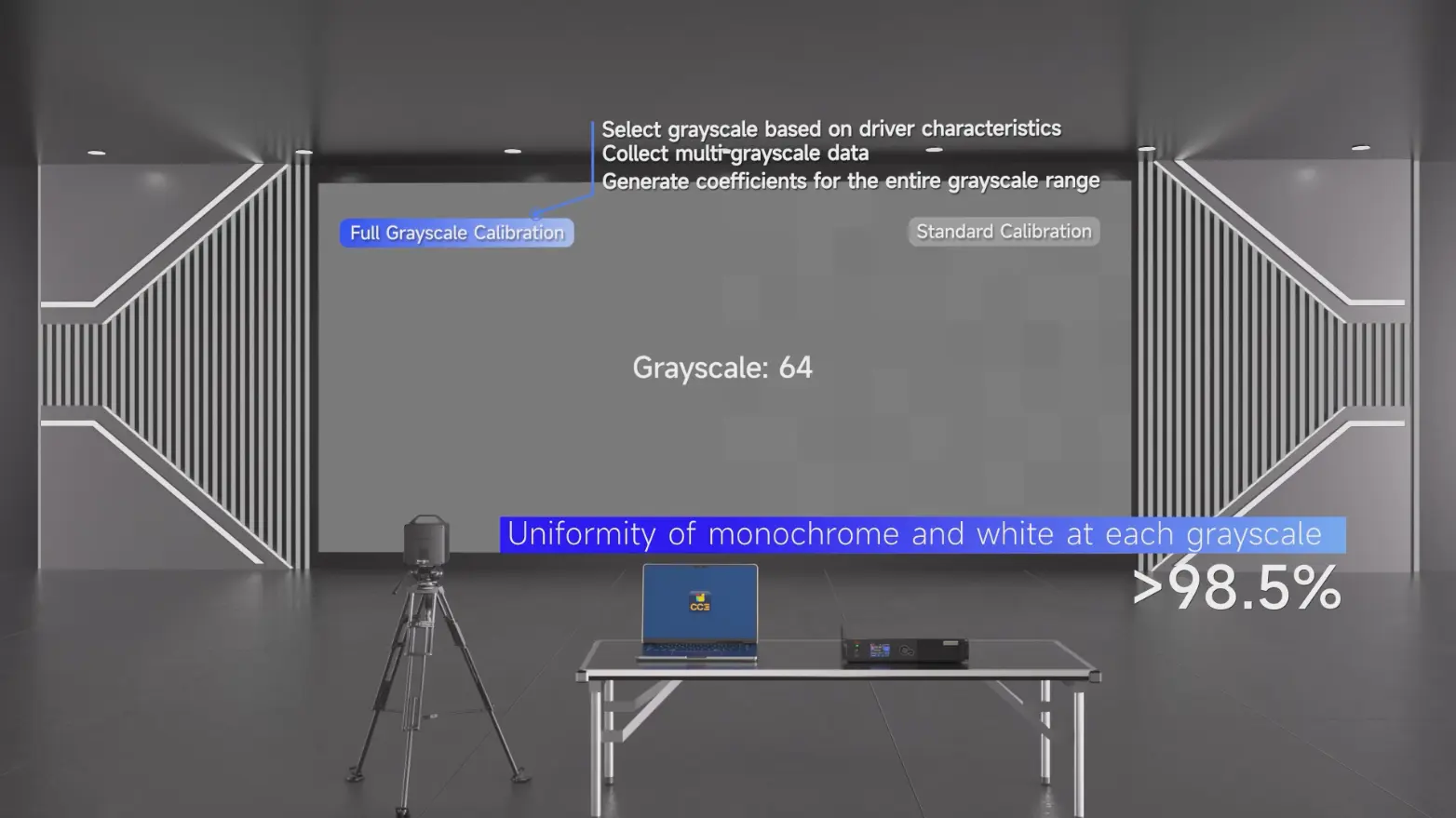

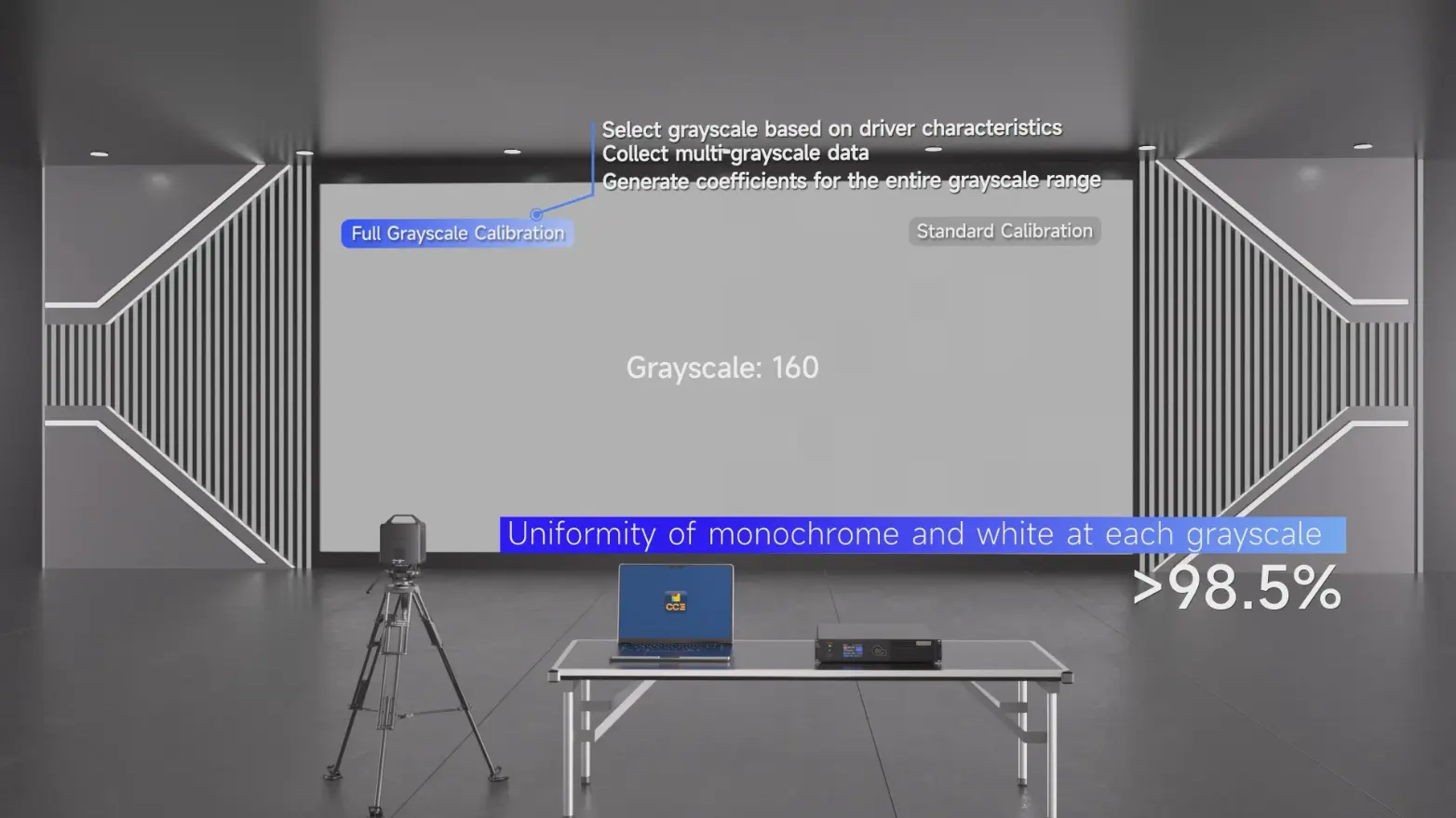

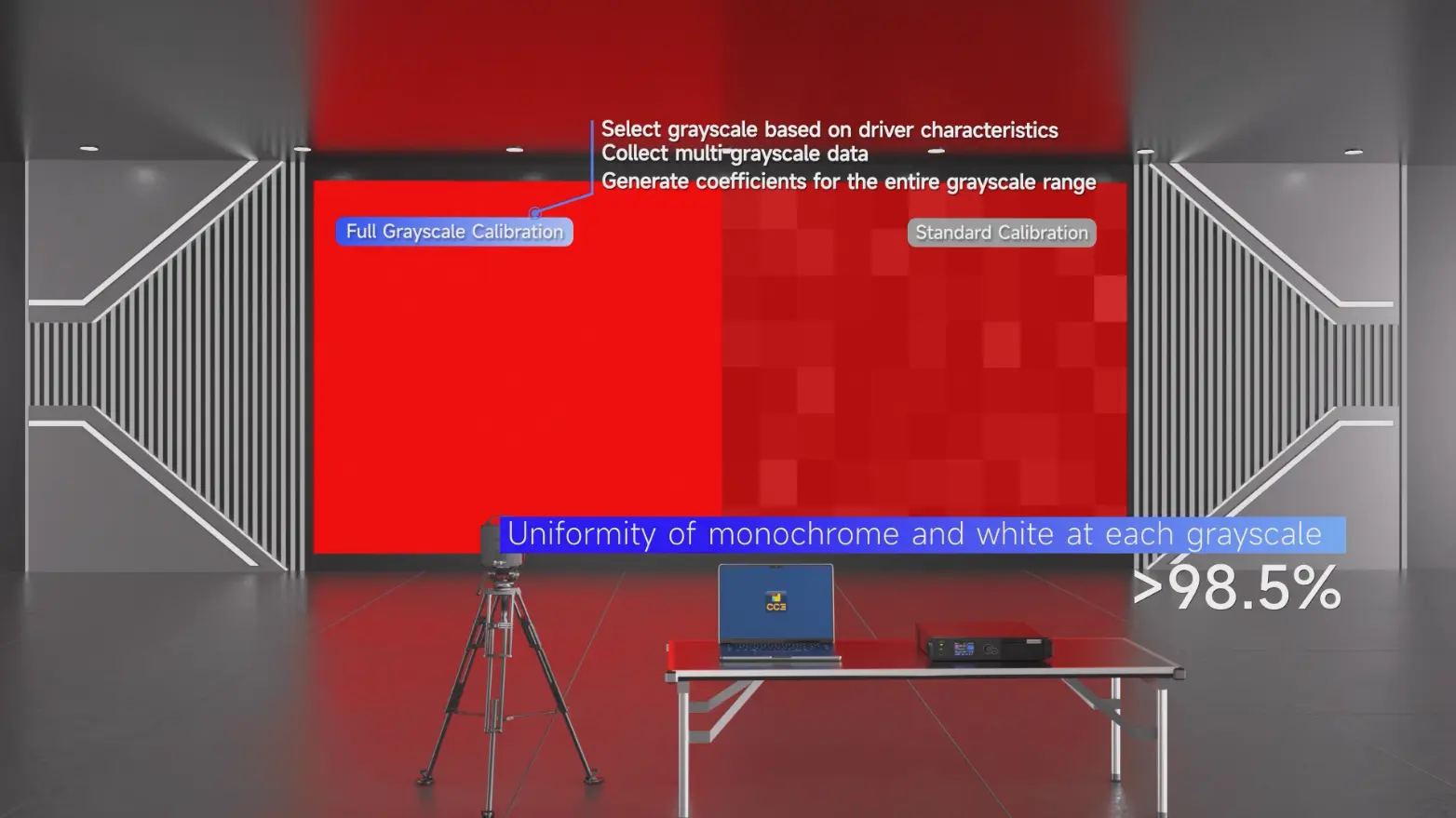

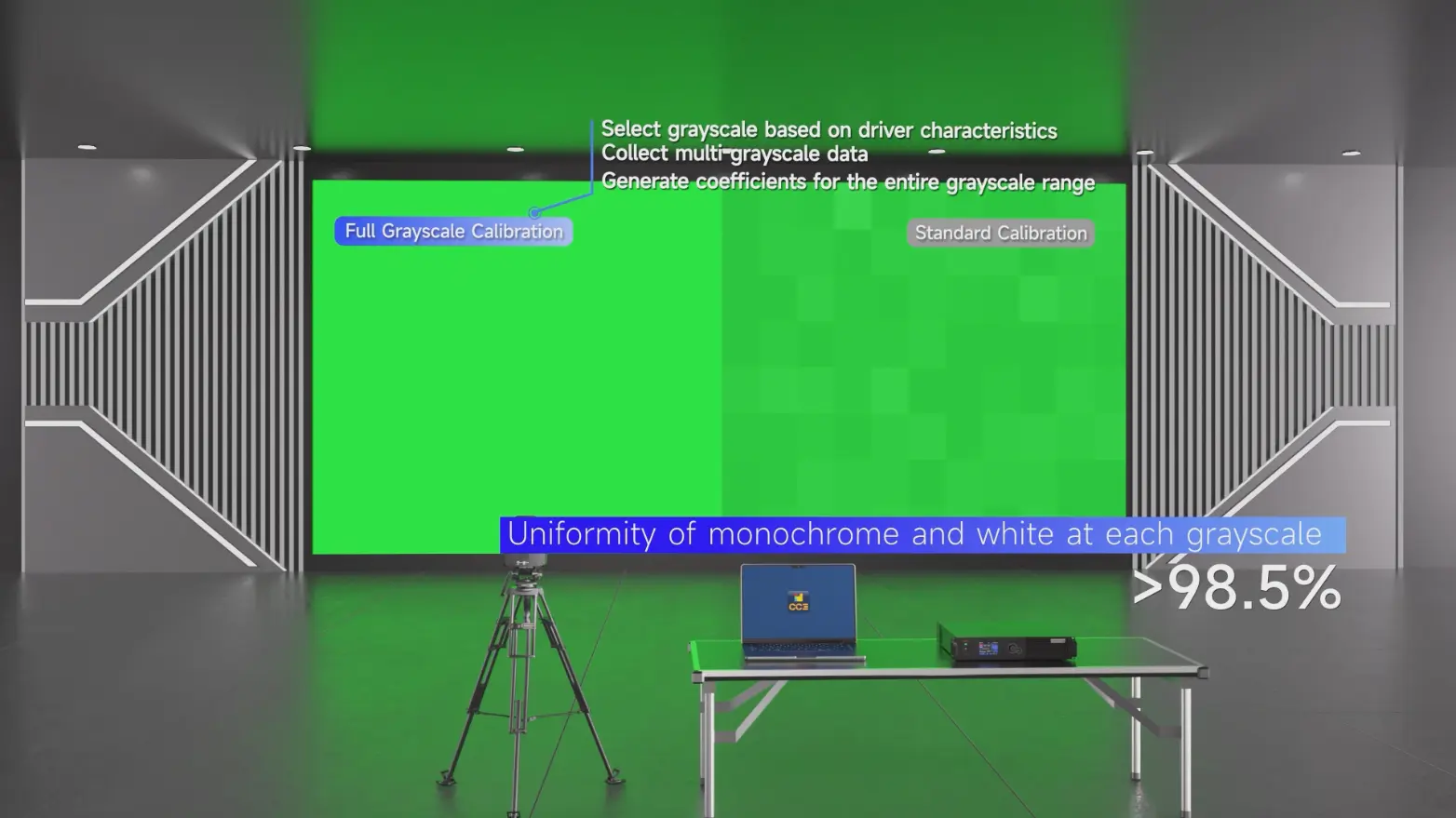

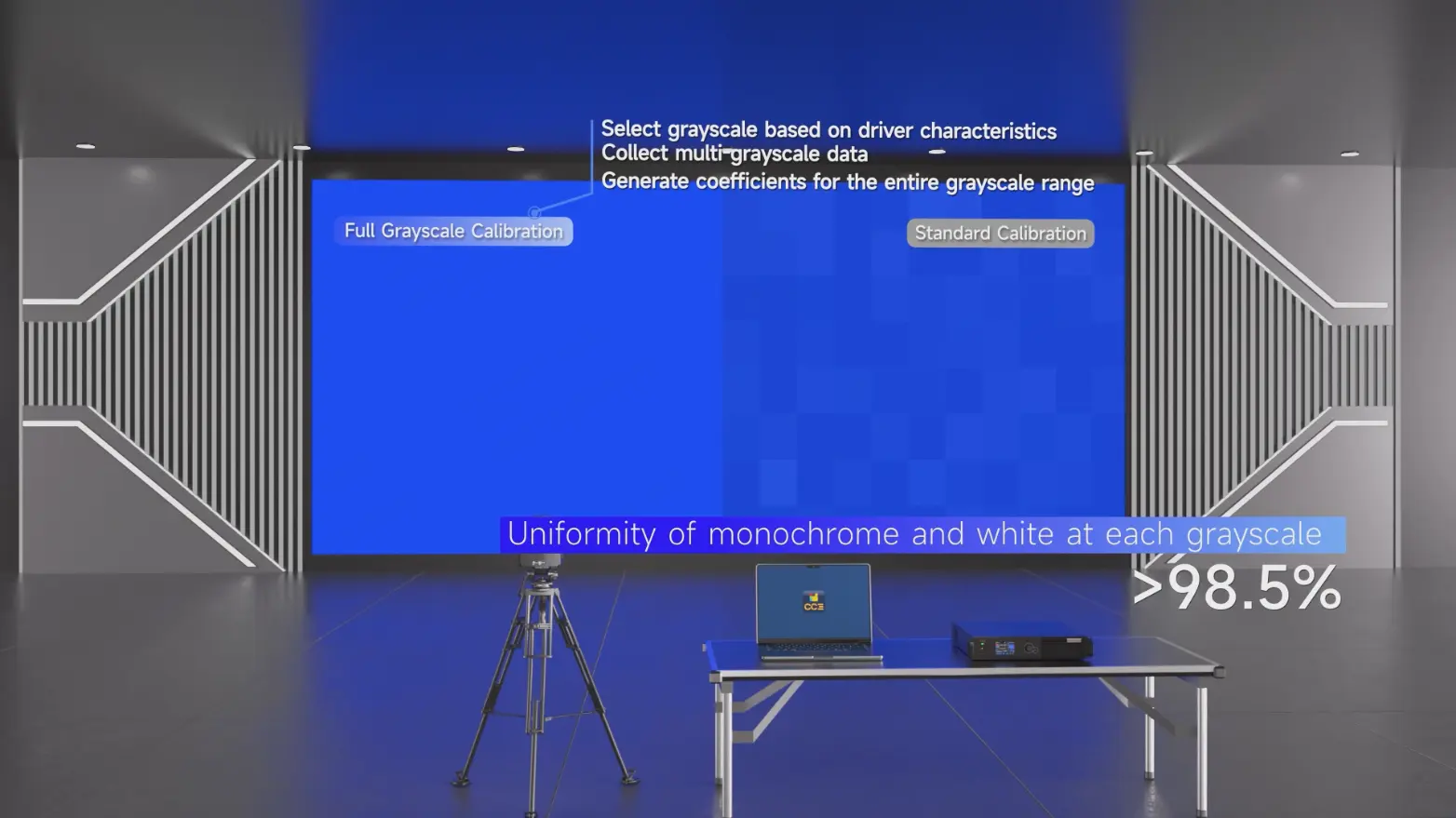

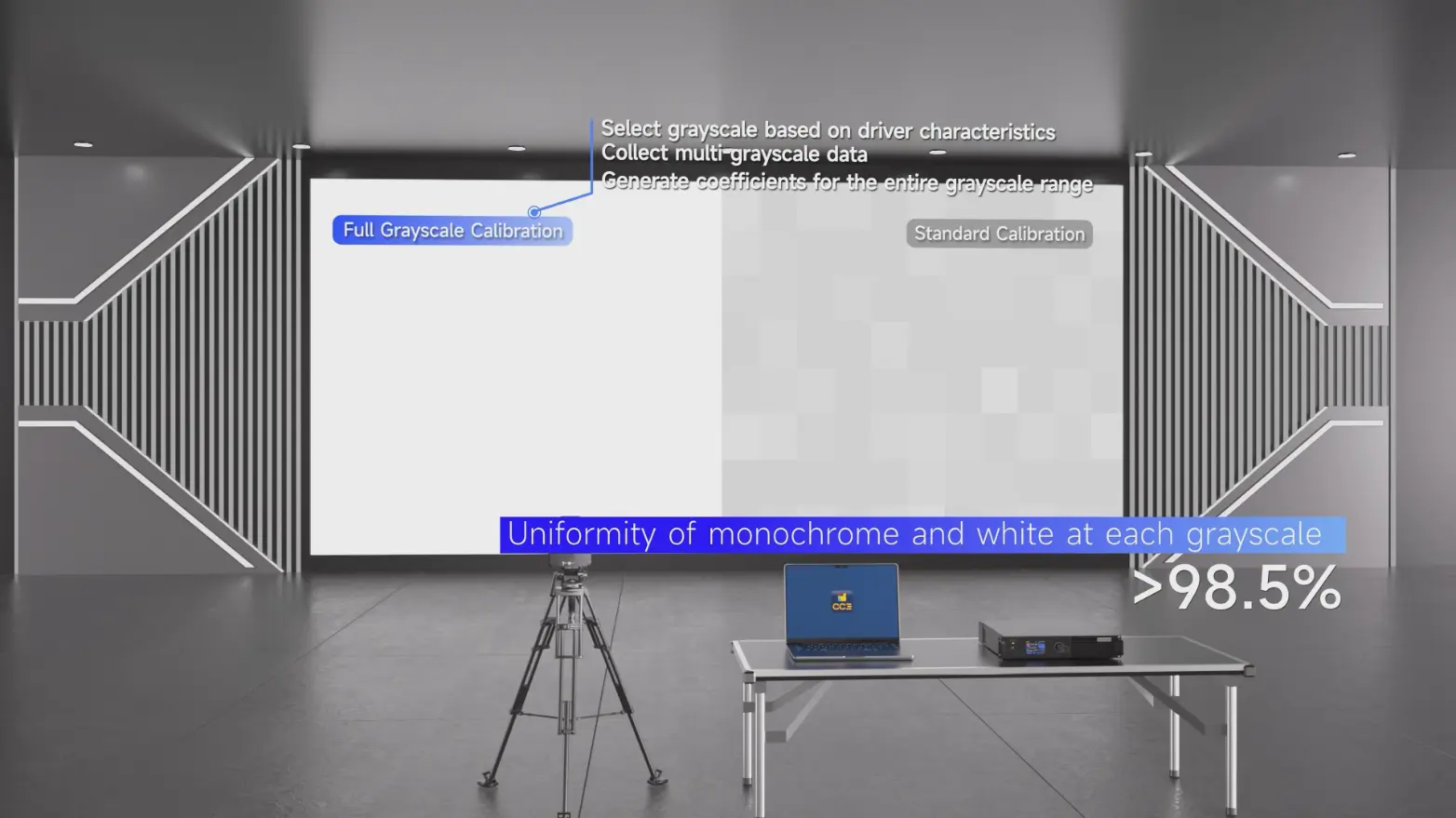

¶ 1. Full Grayscale Calibration

- Implements driver-characteristic-based grayscale selection

- Multi-grayscale data measurement

- Full-range grayscale coefficient generation

- Achieves >98.5% monochromatic/white uniformity across low/mid/high grayscale ranges

- Delivers exceptional visual performance

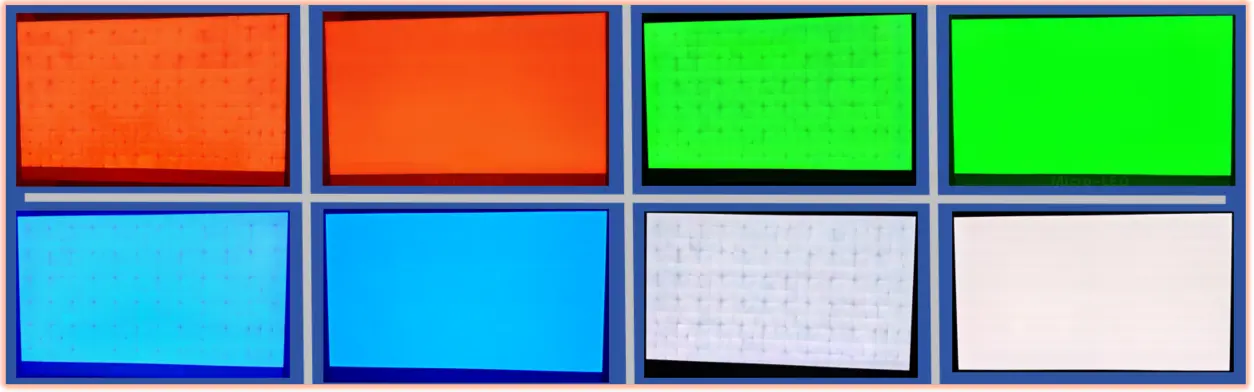

Uniformity >98.5% across all grayscale ranges (low/mid/high) under test patterns

Uniformity >98.5% under RGBW monochromatic test patterns

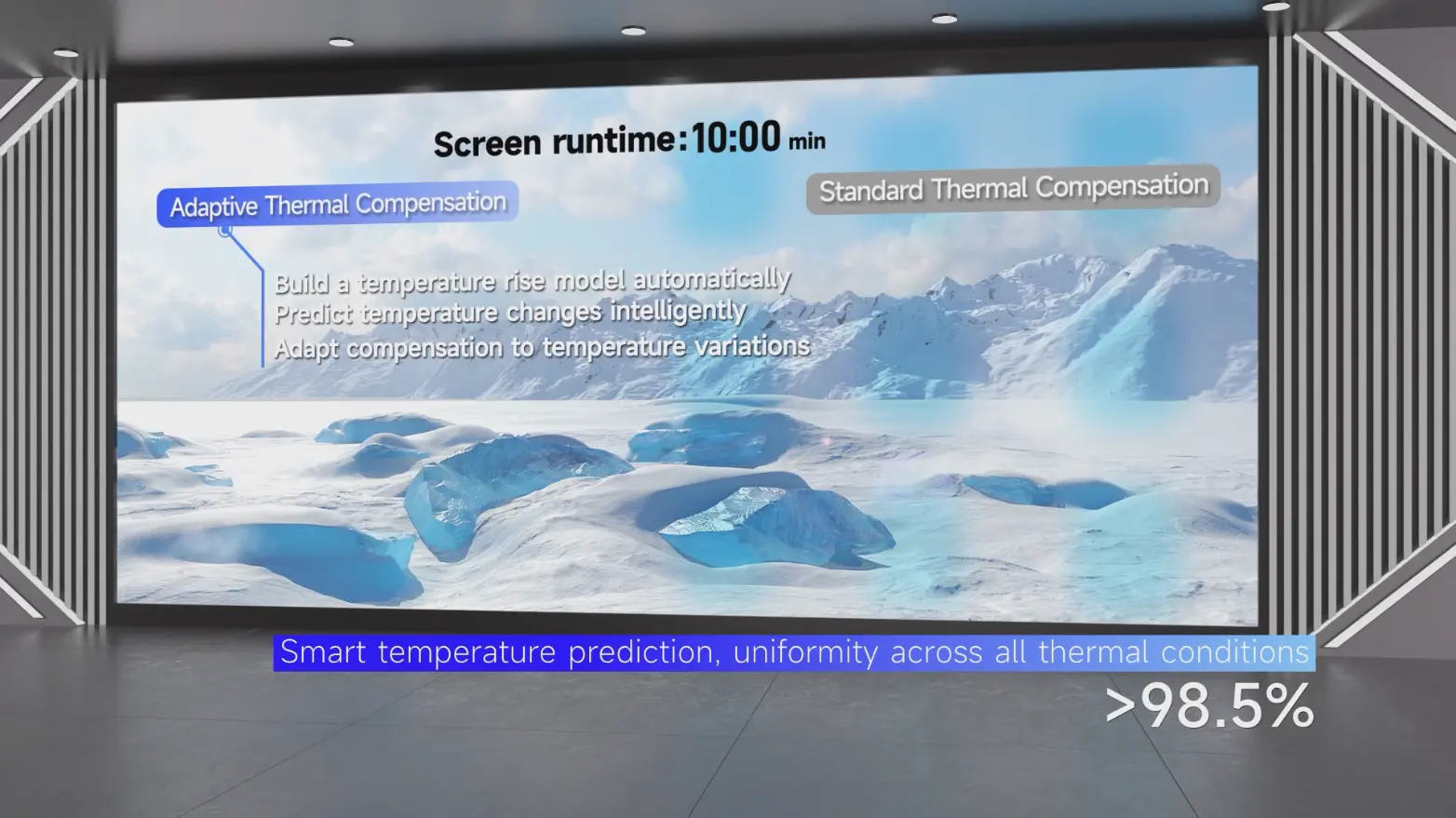

¶ 2. Adaptive Thermal Compensation Technology

- Intelligently predicts temperature differential fluctuations

- Maintains >98.5% uniformity for both cold and warm screens

- Automatically constructs thermal rise models

- Smartly anticipates temperature variations

- Performs adaptive compensation based on thermal changes

- Delivers exceptional performance

The left screen in the figure below has adaptive thermal compensation enabled, while the right screen has it disabled.

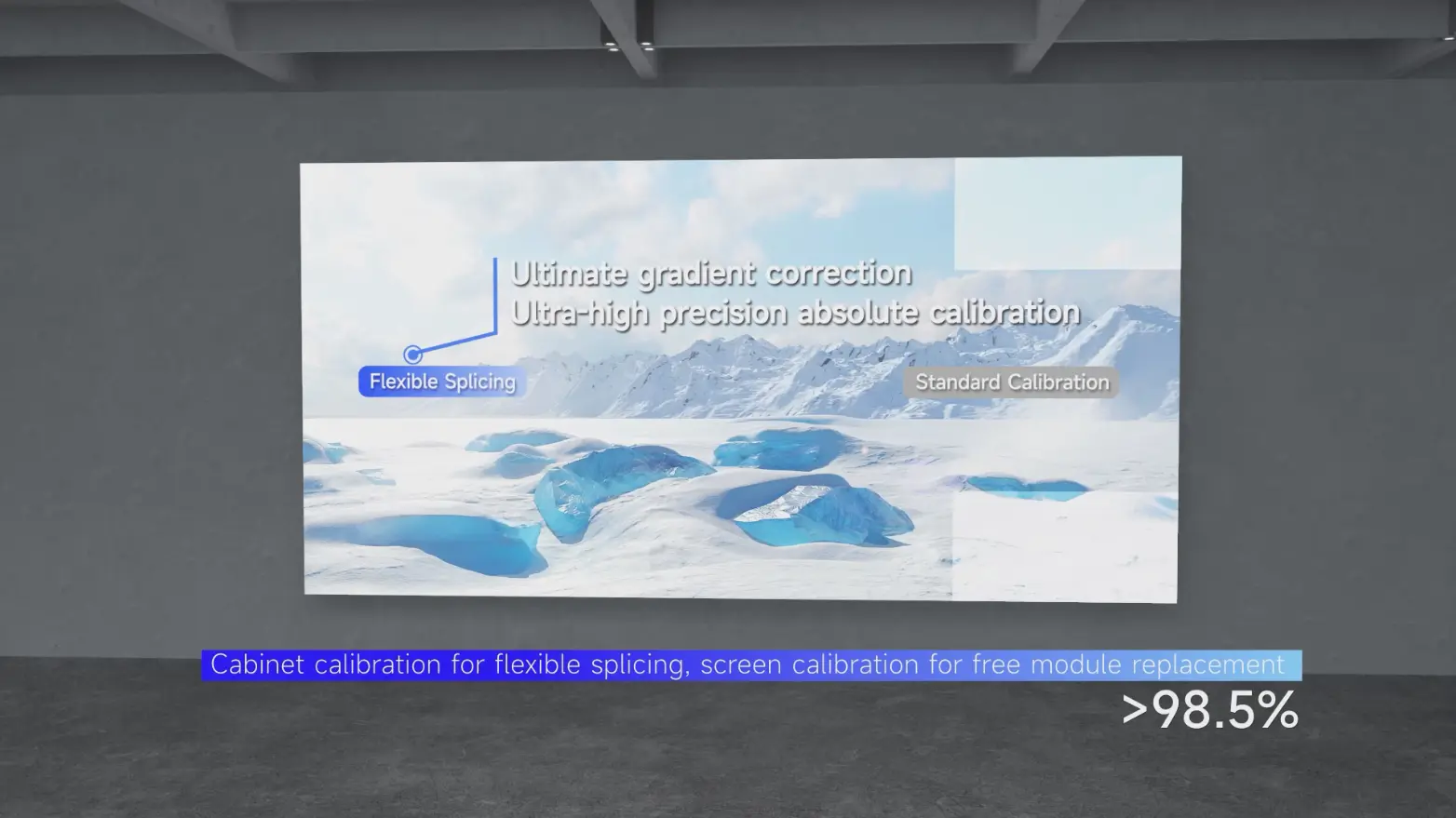

¶ 3. Calibration Calibration with Arbitrary Splicing Technology

- Achieves extreme gradient compensation

- Implements ultra-high precision absolute calibration

Enables: Free cabinet splicing post-calibration and unrestricted replacement of modules in full-screen calibrated systems

¶ 4. MLED Calibration

- Extends micro-level correction to COG (Chip-on-Glass) and enables mass production calibration for COG displays and MIP panels.

¶ NovaStar Calibration's Industry Impact

The Global Benchmark: Mastery of Calibration

Serving 50+ premium display projects worldwide, defining a new era of high-precision LED calibration

¶ Practical Cases: World-Class Project Endorsements--Globally Verified 98.5% Color Consistency

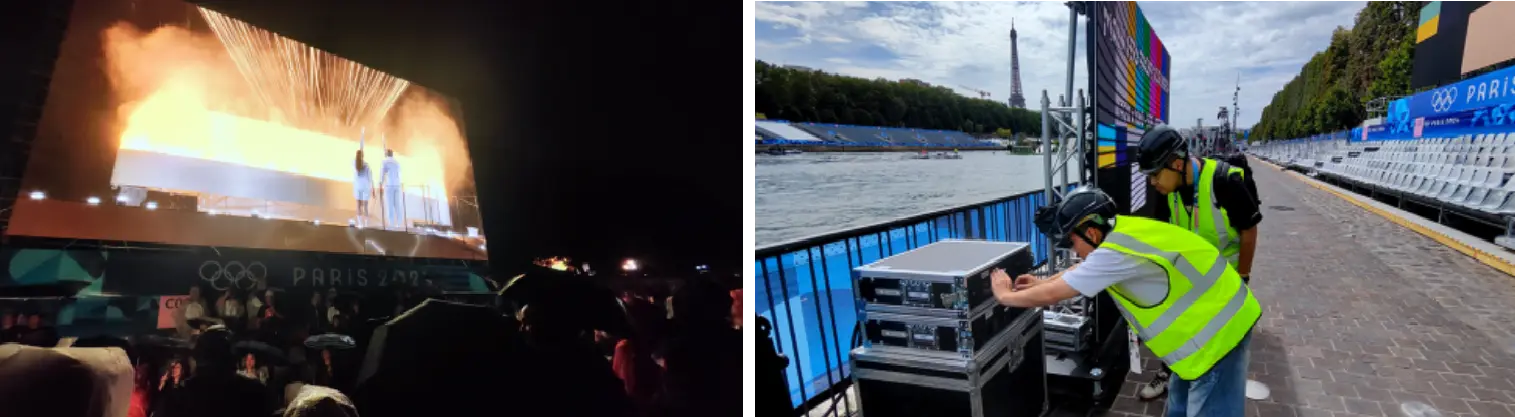

Case 1: 2024 Paris Olympics Opening Ceremony

- NovaStar delivered end-to-end solutions for 90% of LED displays

- Achieved ΔE≤0.003 color deviation (Industry average: ±0.05)

Case 2: 2022 Beijing Winter Olympics Opening Ceremony

- NovaStar provided end-to-end display solutions for all LED screens including:

- World's largest 3D LED stage screen (core visual centerpiece)

- 14,000㎡ integrated display system (floor/ice/torch screens)

- 20 outdoor 8K broadcast screens

Calibration performance and image quality officially recognized by International Olympic Committee

¶ Benchmark Cases: Sports Arena

Case 1: 2008/2012/2016 Olympic Games Support

• Provided calibration solutions for 3 consecutive Olympic editions

• Achieved 98.5% luminance uniformity post-calibration

Case 2: 2018 Russia & 2022 Qatar World Cup Series

¶ Benchmark Cases: Commercial Displays

Case 1: xR and VP Studios

NovaStar has empowered industry leaders to build 50+ professional virtual production stages worldwide, including:

- Yangtze River Delta International Film Center VP Stage (China)

- YaoWang Digital Studio (Shanghai)

- ATM/VU Virtual Stages (North America)

Case 2: Naked-eye 3D Projects

NovaStar-powered 50+ naked-eye 3D screens across China deliver:

- Chengdu Taikoo Li 3D LED Display & Nationwide Projects

- 8K ultra-HD stereoscopic effects

- Photorealistic visual impact (4000nit peak brightness)

¶ Industry Authority: Standard-Setting Leadership-- Authoring Standards, Leading Industry Evolution

Authority in LED Industry Whitepaper Development

NovaStar Co-Authored the 2024 Mini/Micro LED Display Industry Whitepaper as LED Control System Provider

¶ NovaStar's Participation in Global Professional Exhibitions

ISE 2025 (Barcelona, Spain | Feb 2025)

- Full-chain LED/MLED display solutions & innovative products

ISLE 2025 (Shenzhen, China | Mar 2025)

- World Premiere: "Infinity" Hybrid PWM+PAM Driver IC, Greatly Enhance Image Quality of MLED

InfoComm 2023 (Las Vegas, USA)

- Key Support: Provided control systems for Leyard & Unilumin

InfoComm 2025 (Orlando, USA | Jun 2025)

- Global Launch: "Infinity" Control System, Expanding Oversea Market

InfoComm China (2023-2025)

- Smart LED Control System

- Distrubtion System

¶ LED Industry Knowledge

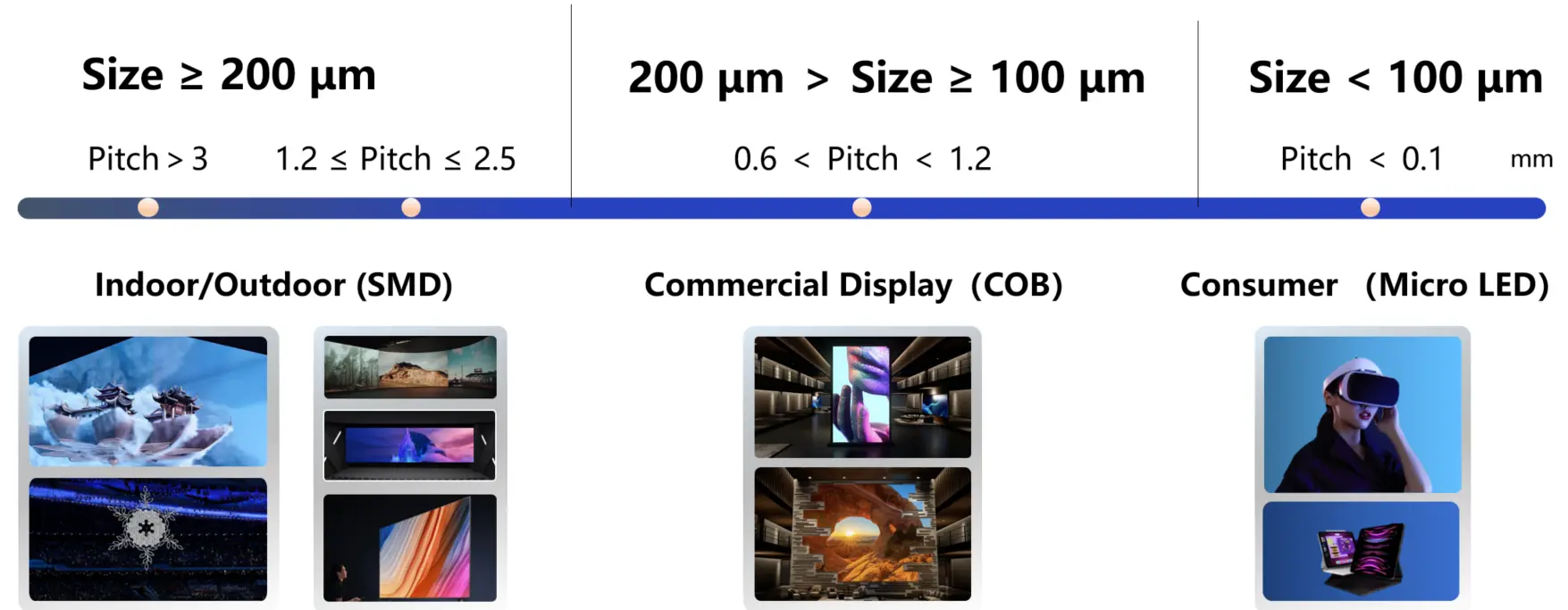

¶ Relationship Between LED Packaging Technologies and Calibration

Surface Mount Device (SMD), surface mount technology. Since SMD packaging technology generally allows the LEDs to be thoroughly "stir-fried" after encapsulation before being mounted on the substrate, the distribution of brightness and chromaticity differences of its LEDs exhibits strong randomness, and the average brightness/chromaticity values between modules/cabinets are very close. At the same time, its pixel pitch is generally above P3, and the current and driving consistency between grayscale levels is relatively good.

Based on the above packaging characteristics, the calibration requirements for such displays are relatively low. Generally, brightness/chromaticity correction using digital cameras or ordinary industrial cameras can meet the uniformity requirements.

Chip On Board refers to directly packaging chips onto a substrate. In the die-bonding stage of COB packaging, chips from different positions on the wafer are placed onto various locations of the substrate using a die bonder. As a result, COB LEDs exhibit less "spatial randomness" in brightness/color compared to SMD, and their mura patterns tend to show certain regularities, such as stripes or blocks.

MIP (MicroLED in Package), on the other hand, involves packaging red, green, and blue chips together before die bonding. Additionally, COB/MIP technologies feature smaller epitaxial chips, enabling a pixel pitch as fine as P0.7. However, the reduced size of driver ICs introduces challenges in current uniformity and channel switching speed consistency, leading to noticeable mura variations across grayscale levels.

Therefore, COB/MIP displays demand higher calibration precision, typically requiring high-accuracy industrial cameras that match human vision, combined with full grayscale calibration, to address complex mura patterns and grayscale inconsistencies. In some cases, low-gray correction via PWM subfield pulse-width adjustment is necessary to achieve uniformity requirements in low-brightness conditions.

COG (Chip on Glass) refers to the technology of packaging chips directly onto a glass substrate. COG enables pixel pitches below P0.4 with further reduced chip sizes. To ensure low current consumption and power efficiency while improving the visual refresh rate at low grayscale, COG typically adopts a hybrid AM+PM (Active Matrix + Pulse Modulation) driving scheme.

Due to the high pixel density per unit area, COG relies on mass transfer techniques for die bonding, which further reduces the randomness of mura patterns. However, COG’s technical characteristics introduce several calibration challenges:

- Complex mura patterns (structured artifacts)

- IR drop (voltage inconsistency across the panel)

- Inter-channel crosstalk

- Mura inconsistency between high and low grayscales

To address these issues, Full Grayscale Calibration is required, incorporating:

- Dynamic current compensation for IR drop

- Decoupling algorithms for channel interference

- Grayscale-dependent mura correction

¶ Full Grayscale Calibration

With the advent of the Mini/Micro LED era, the LED industry continues to scale up production and reduce costs. However, combined with current variations among different chips at fine pixel pitches, non-uniformities in screen brightness and chromaticity become significantly amplified. The main factors include:

- LED Chip Variations: Due to process characteristics during manufacturing (epitaxial growth, die bonding, packaging, etc.), LED chips exhibit non-uniformity in brightness, chromaticity, and lumen maintenance. During die bonding, these epitaxial chips are arranged on the substrate following specific patterns.

- Driver IC Variations: Common issues like current output accuracy and inconsistent channel switching speeds in driver ICs lead to differing mura patterns across grayscale levels.

These two factors result in complex and varying Mura patterns across different channels and grayscale levels on displays, making conventional single-layer grayscale calibration insufficient for higher uniformity requirements. The full grayscale calibration technology, based on driver IC characteristics and incorporating its subfield count and blending features, only requires calibration at specific grayscale levels. The coefficients from each calibrated grayscale level are responsible for the uniformity of a grayscale range, with multi-layer correction coefficients collectively ensuring screen uniformity across all grayscale levels.

¶ Low-Grayscale Calibration

At low grayscale levels during actual operation, due to excessively narrow pulse widths (1-pulse width), inconsistent channel switching speeds cause deviations in the rising/falling edges and ON-time of different chips/LEDs compared to ideal conditions. This variation, combined with inherent differences in the luminescent characteristics of the epitaxial wafers, further amplifies discrepancies between chips and individual LEDs at low brightness levels.

Low grayscale correction technology specifically addresses uniformity variations caused by inherent chip characteristics by compensating the pulse width of individual subfields based on measured brightness differences. After pulse width compensation, the brightness of different ICs and LEDs tends to become consistent.

As the grayscale level increases, the influence of low grayscale correction coefficients on screen uniformity and brightness gradually diminishes due to subfield blending. For mid-to-high grayscale ranges, this effect becomes minimal.

We consistently enhance and refine the content of our Wiki articles.

If you find any mistakes or errors, please contact us.

Your continuous feedback and support will help us further improve our products and content.