¶ 1. What is NCP File

COEX series is NovaStar's flagship control system solution, which introduces several innovative technologies to optimize display quality and user experience. To optimize the application experience of these technologies and ensure the best display performance, while addressing the challenges users face in managing the receiving card configuration file (rcfgx) and firmware, the COEX series introduces the concept of 'integrated management' and the NovaStar Configuration Package file (NCP).

The NCP file integrates the rcfgx, receiving card firmware, image booster file, adaptive thermal compensation file, frame rate adaptive file, and multi-mode parameter file, which completely relieves the difficulties in managing cabinet files, firmware, and other aspects.

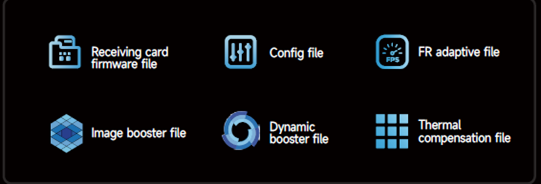

¶ 2. Components of NCP File

The NCP file includes multiple files related to the cabinet configuration, which contains the following six main components.

1. Configuration File

The Configuration File (rcfgx or rcfg file) contains LED module information, cabinet data group, driving IC parameter, refresh rate, GCLK frequency, and other information, which ensures the cabinet can reach the best display effect.

The adjustment of IC parameters is essential for the screen display quality since unreasonable parameters will lead to cross-panel coupling, upper and lower ghost images, color block, low gray color shift, flickering, and other LED screen display issues.

2. Receiving Card Firmware File

Packing the receiving card firmware file into the NCP together can effectively solve the problem of the loss of customized functionality, due to accidentally upgrading the standard version to customized programs, reducing the difficulties in file management and maintenance costs.

3. Frame Rate Adaptive File

This FR adaptive file could make the screen automatically adapt to input sources with different frame rates in the range of 23Hz-240Hz and with steps up to 0.01Hz. Most importantly, the brightness of different frame rates will stay consistent.

Note:

Frame rate adaptive function requires for special IC, and A10s Pro and CA50E can support full frame rate adaptation function.

Please contact NovaStar’s engineers for more information.

4. Image Booster File

Image booster file dedicated to making LED displays accurately perform the brightness and color of the video source, which includes the parameter of 22bit+, precise grayscale, and color management.

22bit+:

64-time enhancement of display grayscale, solving the problem of grayscale loss in low brightness areas, making the dark part of the image richer in detail and the display effect more delicate.

Precise grayscale:

Calibrate 65536 levels of grayscale (16bit) of the driving IC to optimize the display's low gray variation and color jumping, color shift, color pockmarks, etc. Meanwhile, it can better assist the display technology such as 22bit+ and RGB Independent Gamma Adjustment to make the best display.

Color Management:

Supports standard color gamut (Rec.709 / DCI-P3 / Rec.2020) and custom color gamut for more accurate color display.

All paramters files related to the Image Booster will also be included in the NCP file.

Note:

Image Booster Function has the requirement of receiving cards, which are supported by A8s, A8s-N, A10s Plus-N, A10s Pro, CA50E and XA50 Pro.

5. Thermal Compensation File

When the LED screen is running for a long time, due to uneven heat dissipation, some color shifting issue will occur. Through thermal compensation technology, the thermal characteristic of the screen is calibrated, which can effectively solve the color shifting issue.

During the calibration process, screen temperature changes are simultaneously collected. The collected parameters are combined to generate a new thermal coefficient, which is integrated into the NCP file. Users can adjust the thermal compensation strength by VMP sliders, or the system will automatically adjust the strength to solve the color shifting issue of the screen.

Note:

Thermal Compensation tech has the requirement of receiving cards, which are supported by A10s Pro, CA50E, and XA50 Pro.

6. Multi-Mode Parameter File

Multi-mode means that multiple parameter configurations and calibration files for the same LED cabinet are integrated into one NCP. Multi-mode parameter file, also a part of NCP, is loaded by VMP software and provides a switching function in the software interface to meet the user's need for different scenarios.

Multi-mode application scenarios:

Example 1:

Scenarios when a screen needs more than one brightness parameter but can't be adjusted directly by the brightness lever.

(e.g. when the screen needs to switch between indoor and outdoor.)

Example 2:

Scenarios when a user’s screen is limited by its performance, multiple performance parameters cannot be adjusted optimally at the same time.

(e.g. when the refresh rate of the screen is 3840Hz, the effective brightness cannot meet the outdoor need. But if the screen refresh rate is reduced to 1920Hz, although the brightness achieves the standards, it will lead to poor shooting effects.)

¶ 3. Benefits of NCP Management

¶ 3.1 NovaStar and LED Manufacturer Aspects

For the previous rcfgx file, anyone has the authority to produce and modify in NovaLCT, which may lead to some risks:

- The configuration file and the software version do not match.

- The parameter effect may not be the best.

- Unclear rules for naming files.

- The configuration file parameter may not match the LED screen, etc.

To get the best file management, and ensure the accuracy of the NCP, NovaStar strictly controls the NCP license. The NCP production needs Nova’s engineers, IC engineers, and manufacturing designers to complete the three aspects of cooperation and aim for the best effect before shipping.

Note:

All new A10s Pro receiving card cabinets come with NCP by default. For other Amors series receiving cards, the NCP file will be produced when the LED manufacturer has the need.

¶ 3.1 User Aspects

When the user receives the NCP file, it can be imported and saved in the Cabinet Library (pic below) of the controller through the VMP software for file management.

In the latest version of the VMP software, there are Cabinet Library for ensuring synchronization of NCP files between multiple controllers and computers. With this function, users no longer have to worry about losing configuration files. NovaStar believes it could solve the issue of losing files caused by changing controllers or computers for users.

After the application of the NCP file, each type of cabinet corresponds to an NCP file, the user will no longer have the problem of mismatch between the configuration file and the firmware, or the image booster file and different cabinets, which fundamentally saves the cost of the user's file management.

Besides, the NCP system also solves the user's problem of switching configuration files between multiple frame rates for shooting or other multi-frame rate application scenarios. Frame rate adaptive technology enables multiple frame rate configuration files to be combined into one.

¶ 4. NCP Production Process

¶ 4.1 Information Collection

Before the formal production of NCP, all the user's requirements need to be collected.

1. Project Information Collection from Users

Application Scenario

Understand the application scenarios, what functions and effects are concerned about, and what is the most important aspect for Users.

For example:

- VP scenarios: parameter adjustment for different shooting modes and optimizing scan lines would be the most important aspects.

- High-end rentals: The screen’s brightness value and human eye viewing effects would be the most important aspects.

- Cinema: high color accuracy, DCI standards, and P3 color gamut coverage value would be the most important aspects.

Time requirements

Production of NCP files requires a certain amount of time, it will be planned based on LED manufacturers' shipment times.

2. Cabinet Info Collection from Manufacturer

Collecting the LED manufacturer's cabinet information, combined with the user’s requirements, the NovaStar FAE will confirm whether there are design or parameter problems in the cabinet, and communicate with the LED manufacturer.

The collection information includes:

- Cabinet model: for NCP file’s naming

- IC: for understanding IC performance and affecting display.

- Scans: for module design, scan lines in shooting, and chip displays

- Flash IC: for knowing the presence and capacity of Flash IC and the calibration coefficient storage status.

3. Special Requirements Collection from LED Manufacturers or Users

For example, here are some special requirements frequently:

- The Brightness before and after calibration: confirm the brightness value that needs to be achieved after the adjustment.

- Color temperature and White coordinate: confirm the color temperature standard that needs to be achieved after the adjustment.

- Maximum frame rate: confirm the maximum frame rate that needs to be achieved after the adjustment.

- Color gamut: while requirements about color gamut are also collected, users need to be informed of the risks associated with color gamut, which due to the color gamut coverage being determined by the LED beads, adjustment can only affect about 1%.

- Requirements for special functions: whether to require, for example, multi-mode and adaptive frame rate functions, etc.

¶ 4.2 Production of NCP files

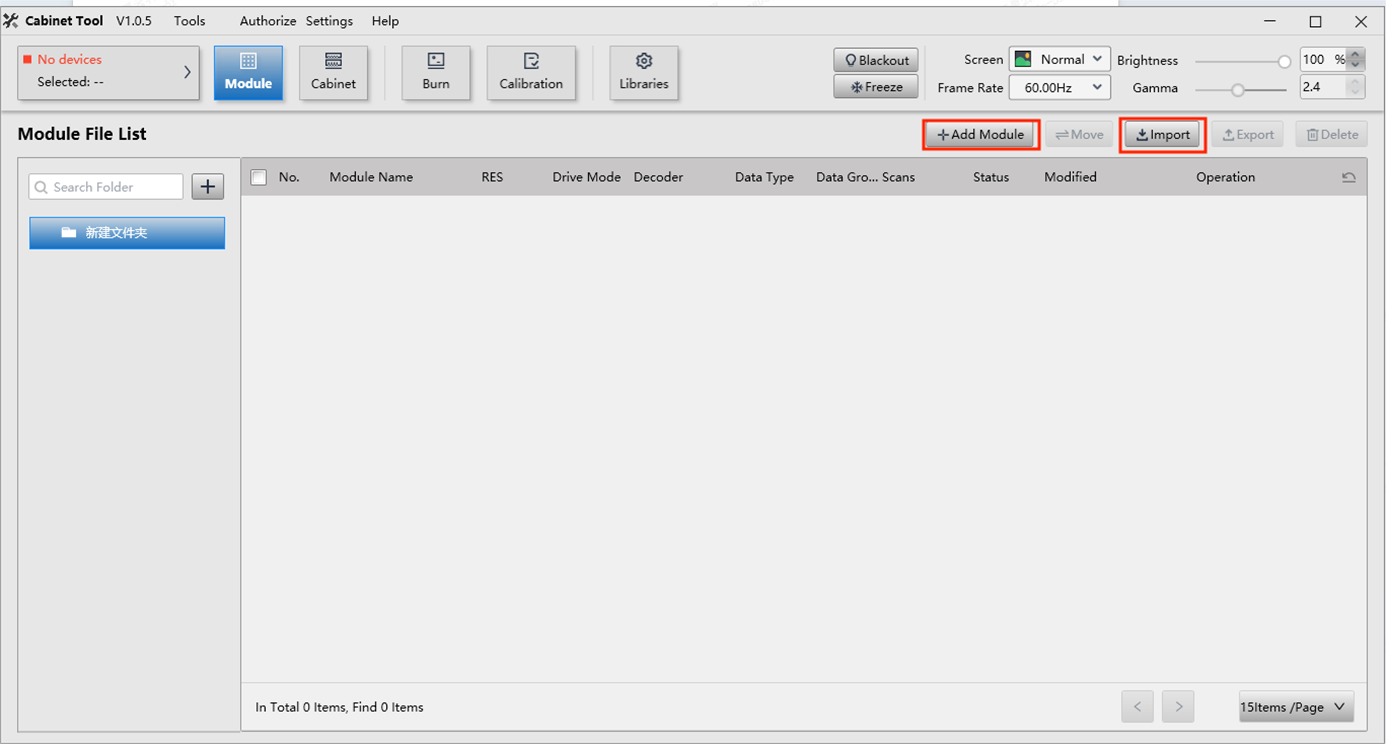

Production of Module File

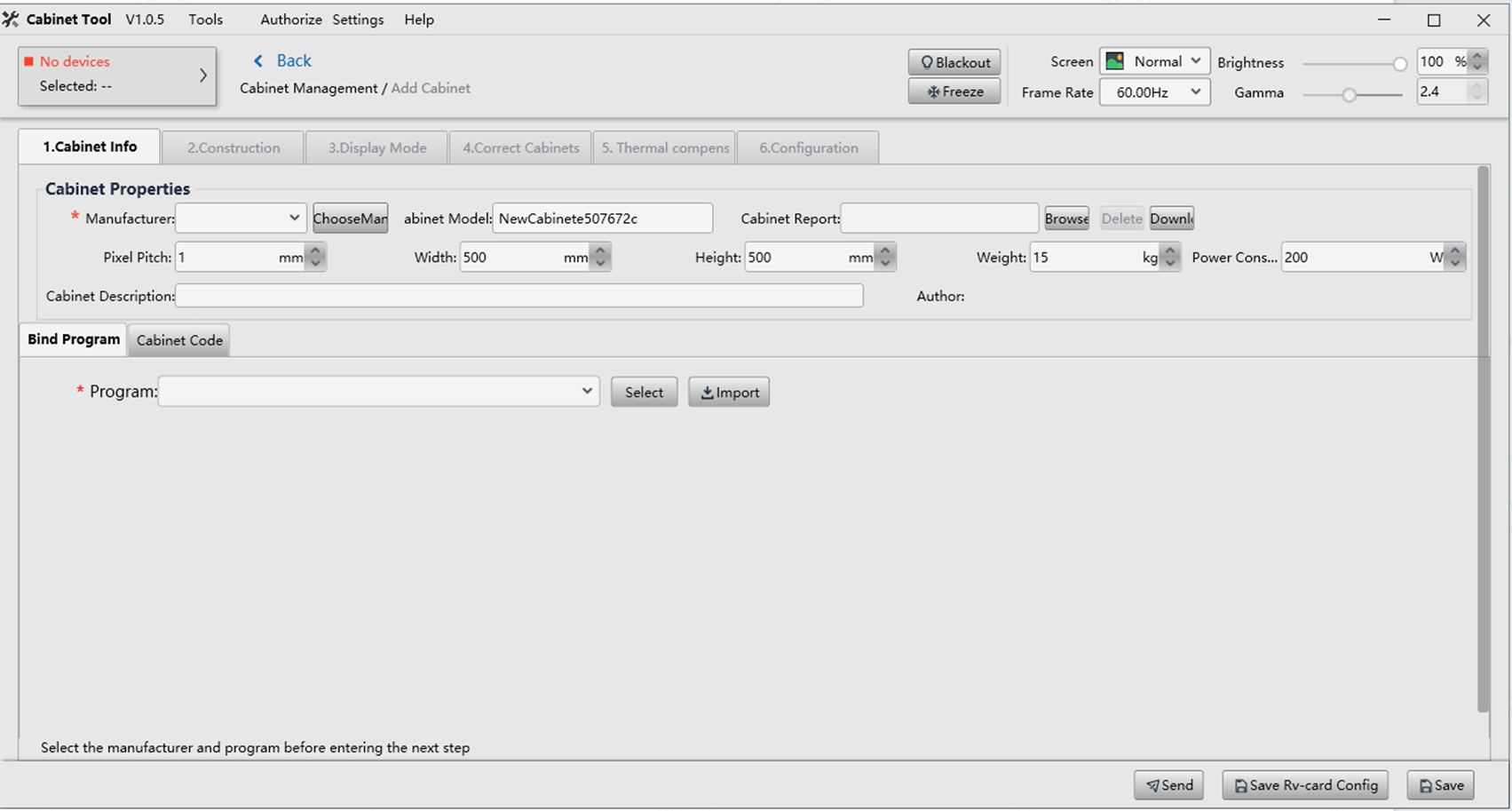

NCP file has an independent “Cabinet Tool” software for production, the following Pic is the main interface of the cabinet tool software. In this interface, click the upper right area “Add Module” button to produce, or directly import the module file from the ‘Import’ button.

This step is to complete the module parameters on the software, which includes the IC information, module size, scans, and data groups. The module file will correspond to the receiving card file to make the module work normally.

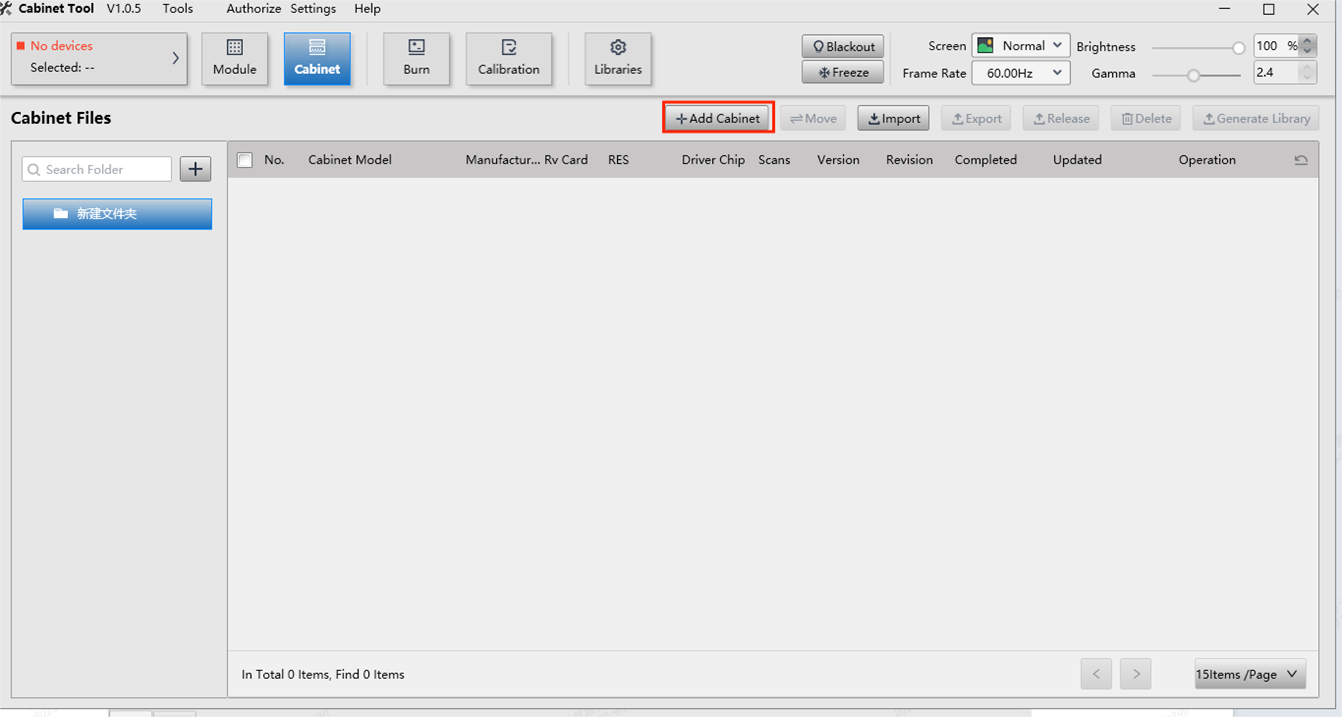

Production of Cabinet File

1. Add Cabinet

After the module file step, it will enter the cabinet file production. The module form in the cabinet will be set in this interface.

2. Import a Firmware

Select the appropriate firmware to write into the cabinet, so that the configuration file and the firmware can be combined into one.

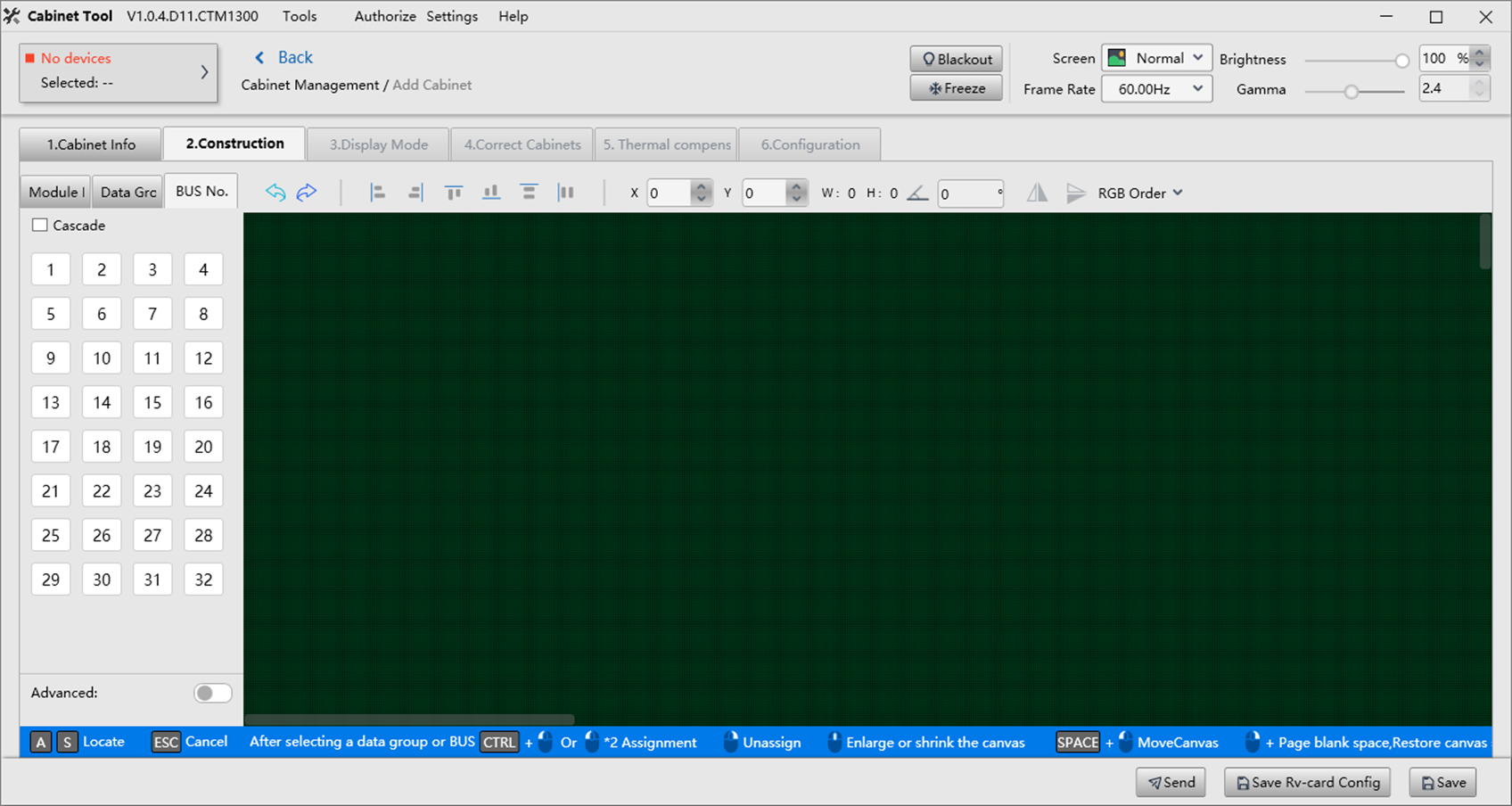

3. Cabinet construction and BUS serial number

Generally, there is an individual Flash IC on the screen module for storing the calibration coefficient. However, since a module usually has multiple Hub ports for data transfer, this interface could sort the Hub ports on a module for sending and reading calibration coefficients from the Flash IC. This order is called BUS No. or Flash No.

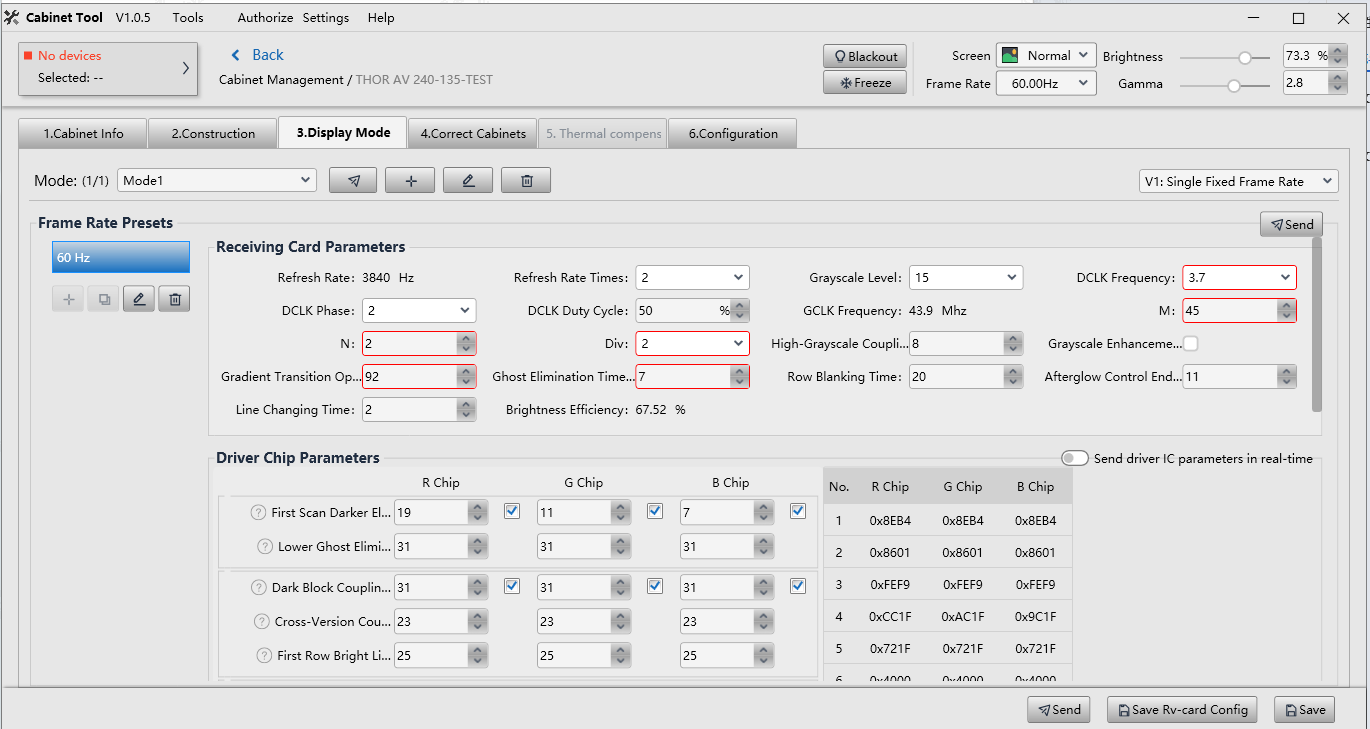

4. Adjustment of Display Mode

In this interface, it could finish the many function adjustments, which include the multi-mode, frame rate-adaptive, and driver IC register parameters adjustment. It could finish corresponding to the IC Register parameters, current gain, and receiving card parameters under different frame rates so that the cabinet can be displayed normally under different modes and frame rates.

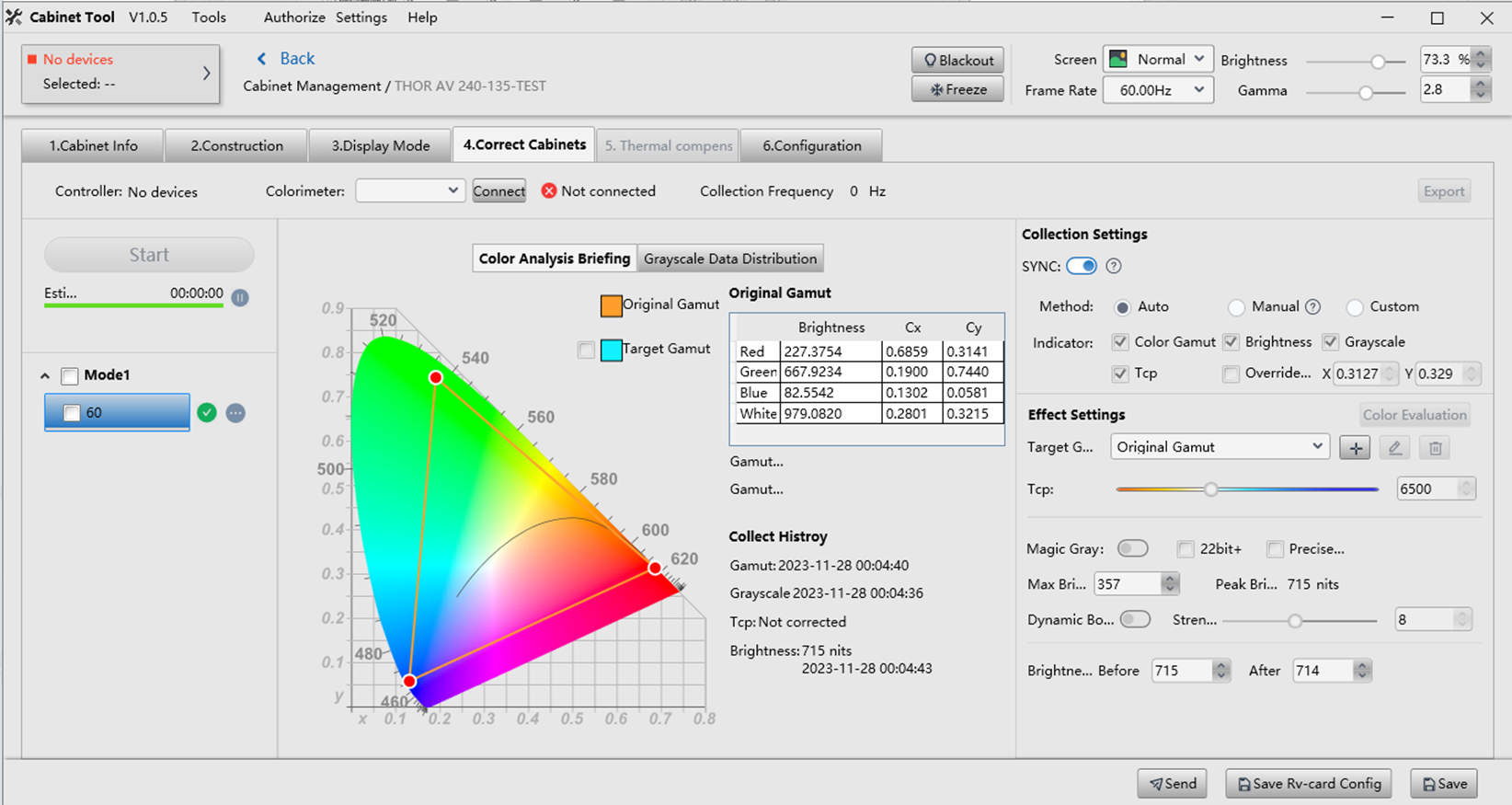

5. Image booster

In this interface, the color gamut, brightness, grayscale, color temperature.

6. Function configuration

The interface is called “Configuration”, it is a collection of function configurations to customize special functions according to the user’s needs, such as function switches. All these function configurations will also be added to the NCP files.

Acceptance of NCP file

After completing the NCP file production, NovaStar's engineers will collaborate with the staff of the LED manufacturer to jointly ensure the NCP display effect is perfect before shipment.

¶ 5. Common Questions

NCP Requirement for New Cabinets

After ordering LED cabinets, if user need NCP file support, please contact LED manufacturer, and they will according to the production rule to contact NovaStar's engineers for NCP file production.

Before the NCP file production, the user needs to fill out the “NCP Requirements Form”. The LED manufacturer will coordinate NovaStar's FAE to get contact, analyze requirements, and provide suggestions for cabinet requirements to ensure that the NCP file can meet the project's requirements.

Note:

If the user orders new A10s Pro LED cabinets but without the NCP file, please contact the LED manufacturer to finish production.

If the user cannot contact the LED manufacturer, please email [email protected] to get NovaStar’s help.

NCP Requirement for User’s Stock Cabinets

If users have NCP file requirements for LED cabinets in the warehouse, please contact LED manufacturer. If the user cannot contact the LED manufacturer, please email [email protected] to get NovaStar’s help.

NCP Adjustment for Existing NCP Files

If the NCP file shipped from the LED manufacturer does NOT meet the project’s requirements, please refer to the requirement for stock cabinets.

¶ 6. Comparison of NCP and Rcfgx Files

|

Comparison Term |

rcfgx |

NCP |

|

Adaptation of Receiving Cards |

All Receiving Cards |

A Series Receiving Cards |

|

Obtained Channels |

LED Manufacturer |

LED Manufacturer |

|

Production Software |

NovaLCT |

Cabinet Tool |

|

Production Staff |

LED Manufacturer’s Engineer /Nova’s Engineer |

Nova’s engineers who has licenses |

|

Adjustment Permissions |

Anyone |

Nova’s engineers who has license |

|

Maintenance Costs |

high |

low |

|

Receiving Card Configuration File |

√ |

√ |

|

Receiving Card Firmware |

× |

√ |

|

Image Booster File |

× |

√ |

|

Thermal Compensation File |

× |

√ |

|

Frame Rate Adaptive File |

× |

√ |

|

Multi-mode File |

× |

√ |

¶ 7. NCP Obtaining Process for Customers

When using the LCT control system, customers often need to adjust the receiving card parameters themselves to achieve better display effects. While when using the COEX control system, customers will receive a pre configured file that does not require adjustment. However, in many practical scenarios, some customers still have a certain requirement for adjusting the parameters of the receiving card. Based on this, this document will provide a detailed explanation of the process of obtaining NCP files when customers have no adjustment abilities.

¶ Guide For Customers To Obtain NCP Files

The flowchart guide for customers to obtain NCP files is as follows

¶ Step 1:Confirmation of Customer Requirements

Customer requirements to be collected at this stage include but are not limited to virtual shooting/high-end leasing/cinema/exhibition hall/indoor/outdoor, etc. (specific application scenarios), and then FAE will evaluate the applicability of the customer’s NCP requirements.

If the customer’s requirements are applicable and the cabinet used in the project meets the NCP making conditions, proceed to step 2.

If FAE determines that the customer’s application for NCP is not applicable, the project will end directly.

Special case: If the customer’s new cabinet is using A10s Pro receiving cards and there is no matching NCP file, FAE will help coordinate and communicate with the LED manufacturer to guide customers to request the LED manufacturer to provide matching NCP files.

Note:

If COEX series products are paired with A10s Pro model receiving cards, and only accept NCP files.

¶ Step 2:Confirmation of Cabinet Information (Filling out the NCP Adjustment Application Form)

Customer Fills out the NCP Adjustment Application Form. FAE checks the risk items in the NCP Adjustment Application Form based on customer's requirements. If there are differences between the customer's requirements and the content of the NCP Adjustment Application Form, FAE will inform the customer to modify the NCP Adjustment Application Form until the project matches the NCP Adjustment Application Form, and then proceed to step 3.

If customer does not fill in the NCP Adjustment Application Form, the project will end directly.

Risk items include but are not limited to:

- Cabinet’s IC does not support customer’s field frequency adaptation requirements;

- The gamut of the cabinet lamp beads cannot meet the customer's requirements;

- The brightness of the cabinet cannot meet the customer's requirements;

- Customer's regular indoor screen requires a frame rate of 3.0, etc.

The Adjustment Application Form is shown below

¶ Step 3:Customer contacts the salesperson and the manufacturer sends backup cabinet to Shenzhen laboratory

Once the cabinet is delivered, proceed to step 4.

If the cabinet cannot be delivered because the cabinet is produced by customers themselves or the LED manufacturer does not have backup cabinets, proceed to step 5.

Note:

The cabinet delivery cost needs to be negotiated and agreed upon by the corresponding sales and the customer. The adjustment time should be at least one week and does not include the delivery time. And once adjustment begins, changes to requirements are no longer accepted.

¶ Step 4:Confirm the Adjustment Requirements with FAE

¶ Step 5:Customer contacts salesperson to send cabinets to the Shenzhen laboratory

If customer completes the delivery, return to step 4.

If customer is unable to send cabinet due to cost and project timeline issues, proceed to step 6.

Note:

The cabinet delivery cost needs to be negotiated and agreed upon by the corresponding sales and the customer. The adjustment time should be at least one week and does not include the delivery time. And once adjustment begins, changes to requirements are no longer accepted.

¶ Step 6:Customer contact salesperson to send cabinets to branch offices

The FAE of the branch office makes NCP for the customer, and after completing the NCP adjustment, proceed to step 8.

Special Case: The branch office does not accept cabinets sent by customers for no reason and NCP making requirements without communicating with FAE. Customers have to communicate with FAE and complete the steps of collecting customer's requirements and cabinet information, the branch office will then undertake the NCP making requirements.

Note:

The cabinet delivery cost needs to be negotiated and agreed upon by the corresponding sales and the customer. The adjustment time should be at least one week and does not include the delivery time. And once adjustment begins, changes to requirements are no longer accepted.

¶ Step 7:FAE go to customer's site to make NCP (Special Case)

FAE will go to the customer's site to make NCP files if all the above conditions are extremely difficult to meet. In this case, travel expenses need to be negotiated and agreed upon between the customer and the salesperson.

FAE completes the NCP adjustment and proceed to step 8.

¶ Step 8:NCP File Delivery

Note:

Due to regulatory requirements, the NCP file name cannot be changed, and FAE will inform customers of the NCP naming conventions.

An example of its naming convention is as follows:

¶ 8. VMP NCP Management

NCP is a file package designed to maximize the display performance and simplify the maintenance for users. It can include Firmware, Configuration File, Image Booster File, Thermal Compensation File, Adaptive Frame Rate File, and Multi-mode File.

Note: The below 3 files are optional, depend on the hardware and customers’ needs.

- Thermal Compensation is exclusive to A10s Pro, CA50E, XA50 Pro.

- Multi-mode is exclusive for COEX controllers.

- Adaptive Frame Rate depends on receiving cards (same as above) and driver IC. For driver IC, pls contact NovaStar to confirm.

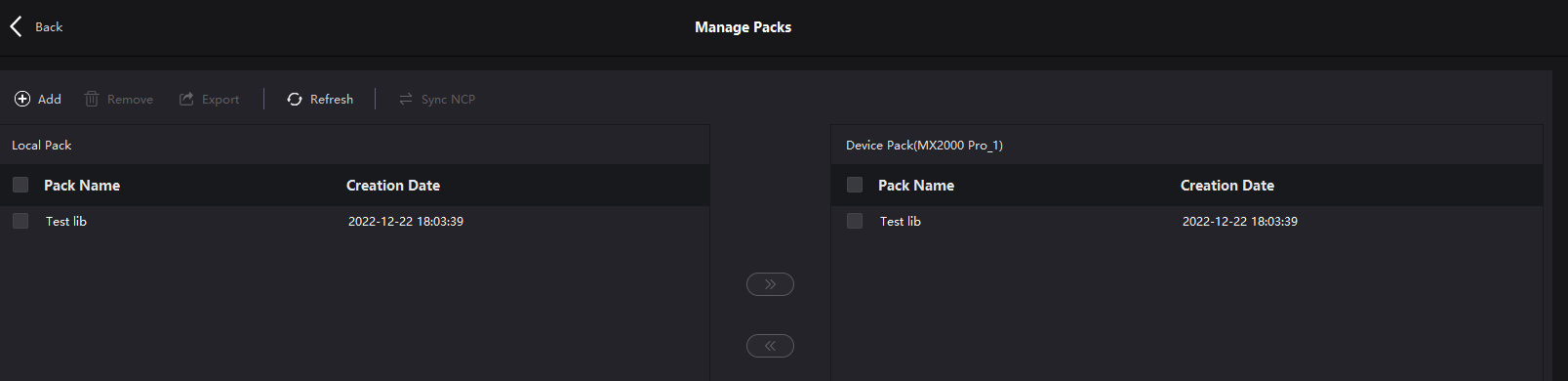

Click on Setting on the top menu bar to enter the cabinet library interface. On the cabinet library interface, all NCP files, parameters and statuses in the software are displayed for users to be managed.

¶ NCP Import

Select any device, click on Setting on the top menu bar to enter the cabinet library interface, and click on Manage Packs in the upper right corner to enter the NCP management interface. Click Add and select the local NCP file to upload to the local pack and device pack.

¶ NCP Sharing Between Devices and Control Computer

In addition, if the user accidentally loses the local NCP file, the NCP sharing operation between the device and the computer can still be easily completed on this NCP management interface.

¶ Common Questions

¶ Which receiving cards support NCP?

NCP supports A5s Plus, A7s Plus, A8s, A8s-N, and A10s Plus-N, A10s Pro, CA50E, XA50 Pro.

- A10s Pro and 5G receiving cards (CA50E, XA50 Pro) are equipped with NCP by default before shipping.

- For other models, users can ask LED manufacturers to make NCP specifically based on their needs.

¶ How can I get the NCP file?

For A10s Pro, the cabinets are equipped with NCP by default. You can contact LED manufacturers to get the NCP file.

For new cabinets with other cards (A5s Plus, A7s Plus, A8s, A8s-N, and A10s Plus-N), please inform the LED manufacturers that you require NCP instead of RCFGX before shipping.

For existing cabinets that don’t have NCP, please contact NovaStar to make the NCP file.

¶ Can I use NCP with other controllers, like MCTRL series, H series, and VX series?

There is no limitation on controllers. You can send NCP via NovaLCT when using MCTRL/ H/ VX series. Check below pic to see how to send NCP.

- Pls note the LCT version needs to be 5.5.0 or above.

¶ If I only have rcfgx file for my cabinets, can I use COEX controllers to control?

First, pls check if the receiving card models are in the range (A5s Plus, A7s Plus, A8s, A8s-N, and A10s Plus-N). For these models, yes, COEX controllers can work together. While for MRV series and DH series, the answer is no.

Below pic shows where to send rcfgx via VMP software.

¶ Notice Download

- Notice Regarding A10s Pro Restrictions on rcfgx Files 0705

- Solution for restricting the use of rcfgx files on the factory with A10s Pro

We consistently enhance and refine the content of our Wiki articles.

If you find any mistakes or errors, please contact us.

Your continuous feedback and support will help us further improve our products and content.